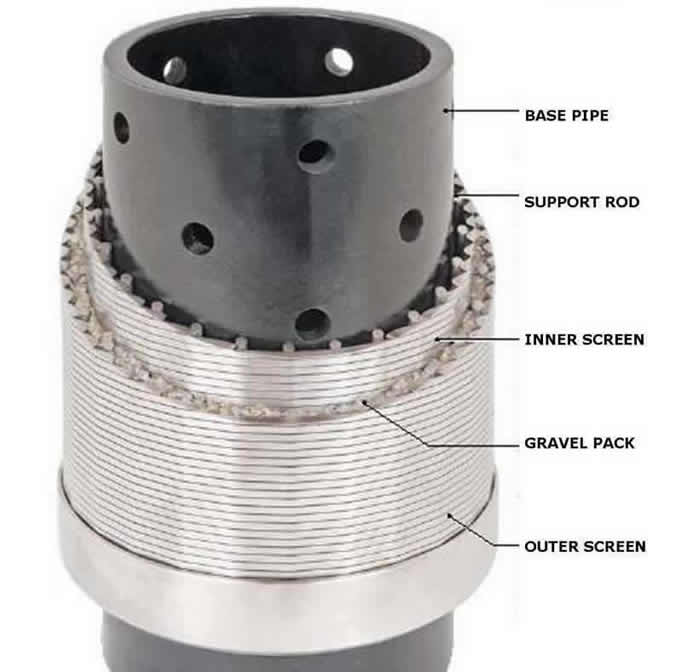

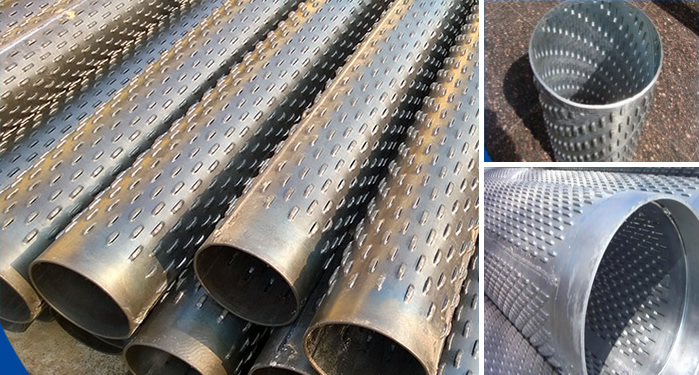

Wire wrapped pre packed sand screen contains perforated base pipe, inner and outer screen jackets and graded sand between the jackets. It is a modification of wire wrapped screen which is used in well sorted sand or stand-alone completion. Graded sand, with or without resin coating, is considered as a filter for reservoir particles.

Sand control is a method to control sand production into a wellbore. This is common requirement for several oil and gas producing wells around the world. There are two situations which cause sand production. The first cause is rock mechanical failure near wellbore and the second one is dragging force from producing or injection fluid. Sand production can lead to several issues such as production impairment due to sand plugging, erosion to completion string and down hole tool, damage surface facilities as separator, piping, etc.

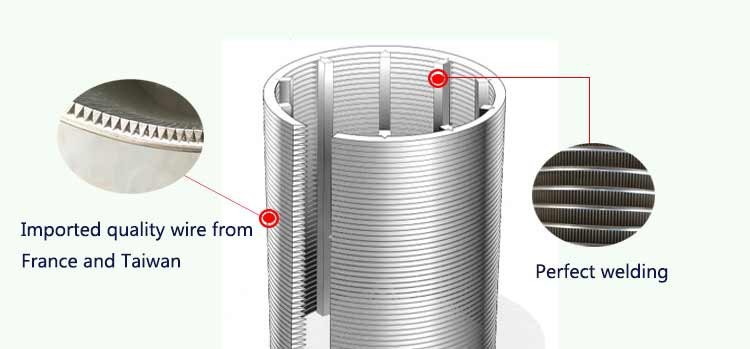

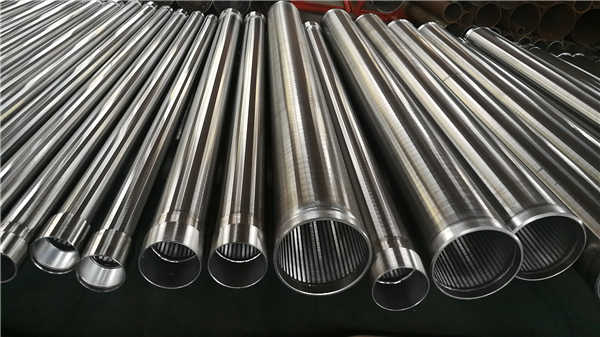

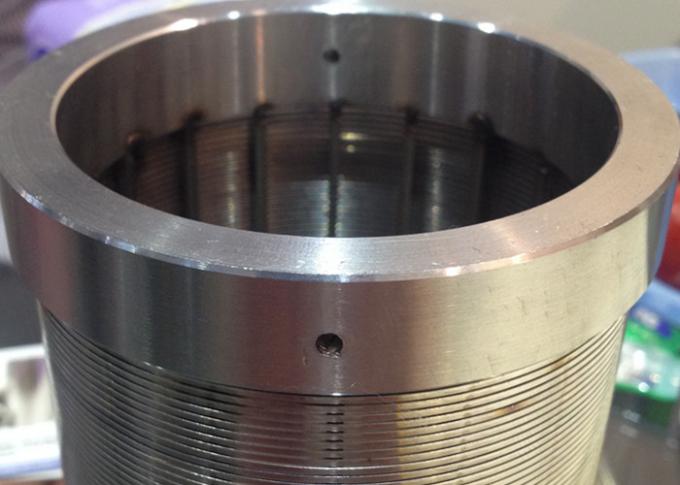

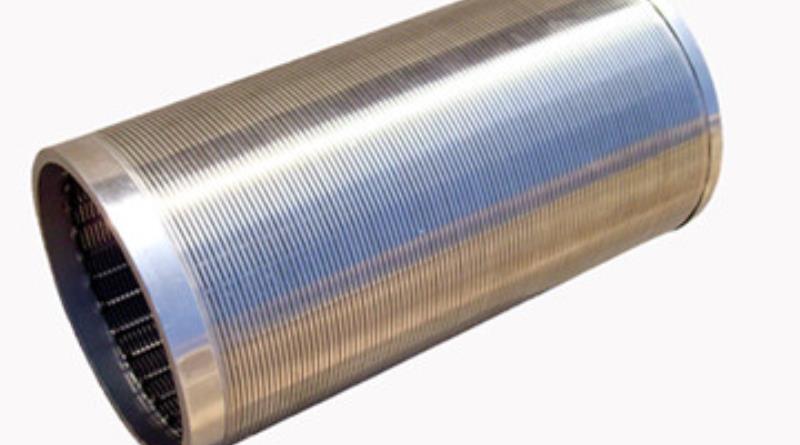

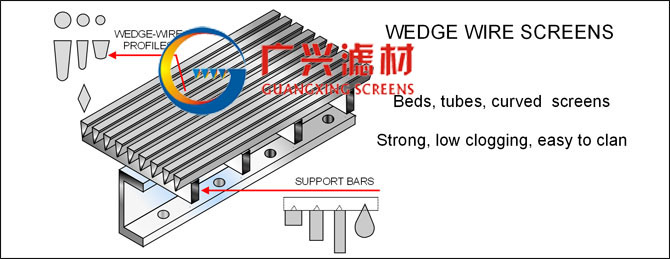

Wire wrapped screen is a perforated pipe with a wire-wrapped jacket welded around. Wires wrapped around the vertical ribs are keystone shaped, which is designed for decreasing the chances of sand plugging the screen because it has a self-cleaning action. It has a bigger flow area in comparison to a slotted liner and it provides good strength and accurate slot opening area.

Wire wrapped pre packed sand screen is ideal for oil or gas completions where gravel pack is not feasible or economical. The screen consists of outer and inner wedge wire screen and perforated base pipe. The sand gravel is resin coated and the size is accompanied by the formation.

There are three main types of wire-wrap screens as listed below;

Rod-based screens

Pipe-based slip-on

Pipe-based direct build screens.

Product description:

Material for wire: stainless steel 316L or nickel alloy 825;

Material for base pipe: upon request;

Wire width: 0.090 in. (2.286mm);

Slot depth: 0.100 in. (2.54mm);

Slot opening: from 50 micron up to 2000 micron.

| Wire Wrapped Sand Screen | ||||||

|---|---|---|---|---|---|---|

| Basepipe OD (in) | Perforations per foot | Basepipe Hole Size (in) | Open Area of Basepipe Holes (in2/ft) | Wrap Wire Size Keystone (in) | Rib Wire Size Round (in) | Maximum OD (in) |

| 1.050 | 54 | 0.3125 | 4.142 | 0.090 × 0.090 | 0.125 | 1.486 |

| 1.315 | 66 | 0.3125 | 5.062 | 0.090 × 0.090 | 0.125 | 1.726 |

| 1.660 | 78 | 0.3125 | 5.983 | 0.090 × 0.090 | 0.125 | 2.126 |

| 1.900 | 42 | 0.375 | 4.639 | 0.090 × 0.090 | 0.125 | 2.387 |

| 2.063 | 42 | 0.375 | 4.639 | 0.090 × 0.090 | 0.125 | 2.55 |

| 2.375 | 54 | 0.375 | 5.964 | 0.090 × 0.090 | 0.125 | 2.862 |

| 2.875 | 66 | 0.375 | 7.289 | 0.090 × 0.090 | 0.125 | 3.362 |

| 3.250 | 78 | 0.375 | 8.615 | 0.090 × 0.090 | 0.125 | 3.737 |

| 3.500 | 78 | 0.375 | 8.615 | 0.090 × 0.090 | 0.125 | 3.987 |

| 4.000 | 90 | 0.375 | 9.94 | 0.090 × 0.090 | 0.125 | 4.487 |

| 4.500 | 102 | 0.375 | 11.266 | 0.090 × 0.090 | 0.125 | 5.001 |

| 5.000 | 114 | 0.375 | 12.591 | 0.090 × 0.090 | 0.125 | 5.506 |

| 5.500 | 126 | 0.375 | 13.916 | 0.090 × 0.090 | 0.125 | 6.011 |

| 6.000 | 126 | 0.375 | 13.916 | 0.090 × 0.090 | 0.125 | 6.515 |

| 6.625 | 138 | 0.375 | 15.242 | 0.090 × 0.090 | 0.125 | 7.147 |

| 7.000 | 150 | 0.375 | 16.567 | 0.090 × 0.090 | 0.125 | 7.526 |

| 7.625 | 162 | 0.375 | 17.892 | 0.090 × 0.090 | 0.125 | 8.157 |

| 8.625 | 186 | 0.375 | 20.543 | 0.090 × 0.090 | 0.125 | 9.167 |

| 9.625 | 210 | 0.375 | 23.194 | 0.090 × 0.090 | 0.125 | 10.177 |

| 10.75 | 234 | 0.375 | 25.845 | 0.090 × 0.090 | 0.125 | 11.314 |

Product Features: 1, no blockage: the cross-section of the screen surface is triangular, the gap on the screen is formed by the two sharp angles adjacent to the two surface filaments, which are contacted by the two sides of the gap when the solids pass through the screen, so that the solid particles on the screen are theoretically either trapped on the screen or through a screen slit, It is impossible to form a third blocking state.

It is very important to reduce the operating resistance of the equipment, to maintain a good hydraulic distribution and to enhance the effect of resin washing.

2, high strength: Because this element uses the stainless steel wire around the welding structure, therefore has the very high strength, this kind of screen can cut on the grinding wheel cutting machine, also may in the lathe processing end face without causes loose deformation. 3, the flow of large: This screen has a relatively small resistance, and the shape of similar size of the plastic filter compared to greatly increase its flow area, so under the same resistance, the flow of the obvious increase.

In other words, with the same output, the number of filter cartridge can be reduced accordingly.

4, the adaptability of the temperature change is good: obviously compared with the ordinary plastic filter, Rainer Company Stainless steel wire screen for the temperature of the applicable range than the plastic filter is much wider. 5, Clearance adjustable: Different users, the use of different filtration equipment and filter media, the internal winding screen of the wire gap between the requirements are different. Because this screen is in the special equipment constantly around the welding, so the gap between the stainless steel trapezoidal wire can be adjusted. In this way, can not increase the cost of the premise to meet the needs of different users, and plastic production of the filter to adjust the gap must be made to the mold, so it is not easy to meet the special needs of users.

A small gap can reach 20 microns.

6, corrosion resistance: for neutral water, acidic water, alkaline water, renewable agent caustic soda, hydrochloric acid, sulfuric acid, salt, etc., as long as the rational selection of these materials, can be economically and safely run all kinds of filtration equipment. Connection mode: Threaded connection, flange connection