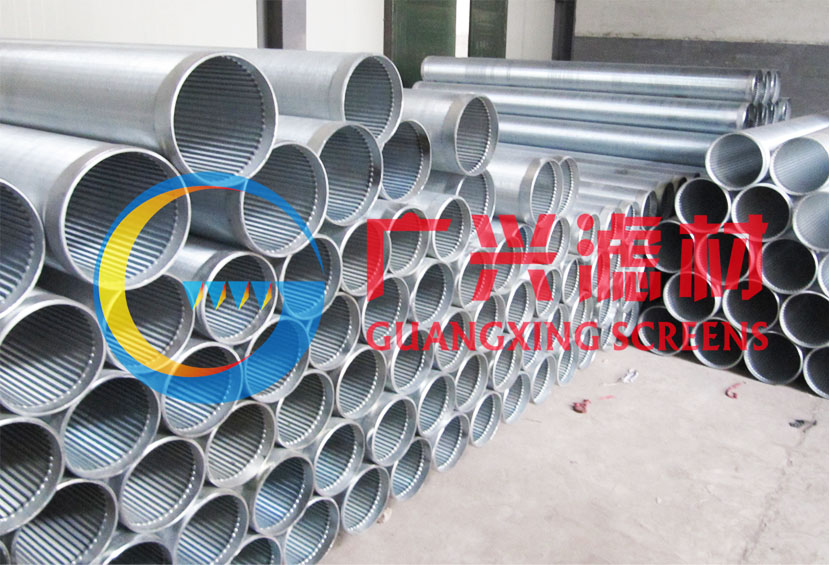

Water Well Screen Pipe

Water well screen pipes are critical components in the construction and maintenance of water wells. They are designed to filter out sand and sediment from water while allowing optimal water flow into the well. This document provides a detailed overview of water well screen pipes, including their materials, characteristics, uses, features, and advantages.

Materials

Water well screen pipes are typically made from two primary materials:

- Carbon Steel

- Stainless Steel:

- 302

- 304

- 304L

- 316

- 316L

Characteristics

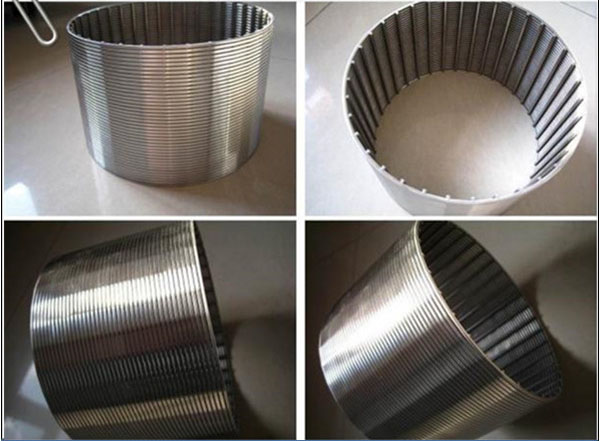

The welded stainless steel water well screen is composed of rods and warp. The rod can be round wire, triangular wire, or trapezoid wire, while the warp is triangular wire (also known as V-shaped wire). These screens are known for their structure, high open area, and accurate slot dimensions. Additional characteristics include:

- Heat-Resistant

- Anti-Corrosive

- Good Mechanical Capability

- Long Lifespan

- Safety and Reliability

Uses

Water well screens are versatile and can be used in various applications, including:

- Deep Well Pumps

- Dive Water Pumps

- Water-Treatment Equipment

- Environmental Protection

- Sea Water Desalination for Industrial and Domestic Use

- Running Water Treatment

- Water Softening Treatment

- Petroleum Industry: Used as terminal filters for petroleum products.

- Chemical Industry: Filters for acidic and alkaline liquids.

- Alcohol and Organic Solution Recycling Filters

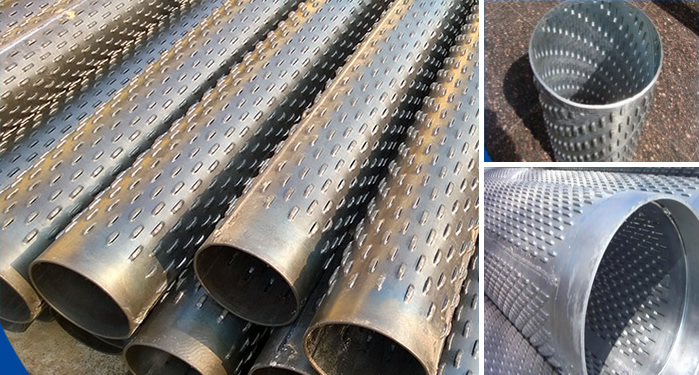

Features of Products

Water well screens come with several distinctive features:

- Continuous Slot Opening:

- Significantly increases the available open area.

- Provides greater access to the water-bearing zone.

- V-Shaped Profile Wire:

- Avoids clogging.

- Ensures uninterrupted flow.

- Uniform and Efficient Well Development:

- Facilitated by the continuous slot opening.

- Ladder-Like Wire Welded Screens:

- Strong structure with high open area.

- Accurate slot dimensions.

- Easy backwashing.

- Long lifespan.

- Safety and reliability.

- Low comprehensive cost.

Advantages

Water well screen pipes offer numerous advantages:

- High Open Area:

- Suitable for high-quality water, oil, and gas wells.

- Promotes better groundwater infiltration.

- Reduces water level drawdown, saving energy.

- Low Cost Operation:

- Screens with high open area favor groundwater infiltration, reducing energy consumption.

- Reduced Pump Abrasion:

- The high open area allows groundwater to enter the screen at a slower speed, reducing sand entry and pump abrasion.

- Extended Lifespan of Wells:

- Easier groundwater entry through high open area screens.

- Slower water flow extends the lifespan of wells.

Conclusion

Water well screen pipes, particularly those made from stainless steel and carbon steel, are essential for efficient and reliable well operation. Their design, featuring high open areas and V-shaped profile wires, ensures that they provide optimal filtration while maintaining a high flow rate. These characteristics make them invaluable in a wide range of applications, from water treatment to industrial processes. By reducing pump abrasion and extending well lifespan, they offer both operational and economic benefits, ensuring that water wells function efficiently and sustainably over the long term.