Comprehensive Guide to Stainless Steel Pipe Base Screens

Introduction

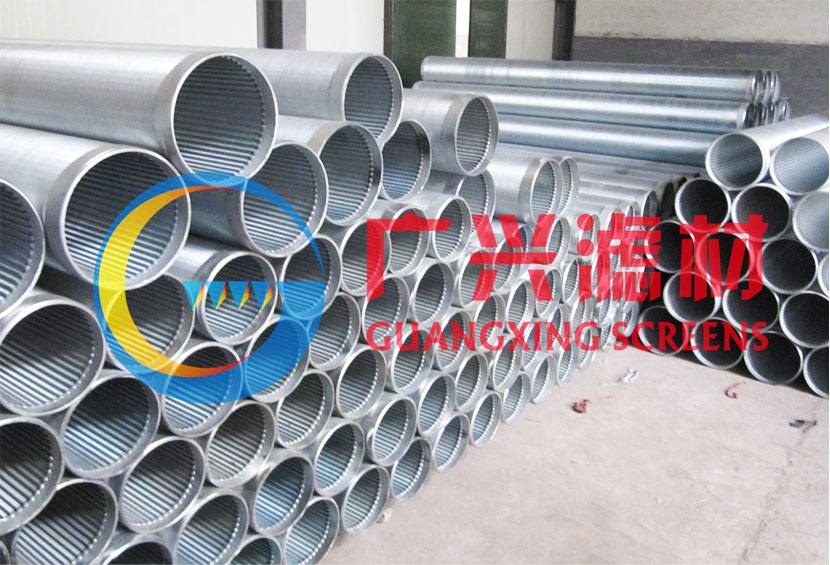

Stainless steel pipe base screens are integral components in various industrial applications, particularly in the oil and gas industry, water treatment, and filtration systems. These screens are designed to provide high strength, excellent corrosion resistance, and efficient filtration capabilities. This article delves into the technical aspects of stainless steel pipe base screens, exploring their design, benefits, applications, and technical specifications.

Understanding Stainless Steel Pipe Base Screens

What Are Pipe Base Screens?

Pipe base screens are cylindrical filtration devices used to prevent the ingress of unwanted particles while allowing the passage of fluids. They are typically constructed from stainless steel, known for its durability, corrosion resistance, and strength.

Components of Pipe Base Screens

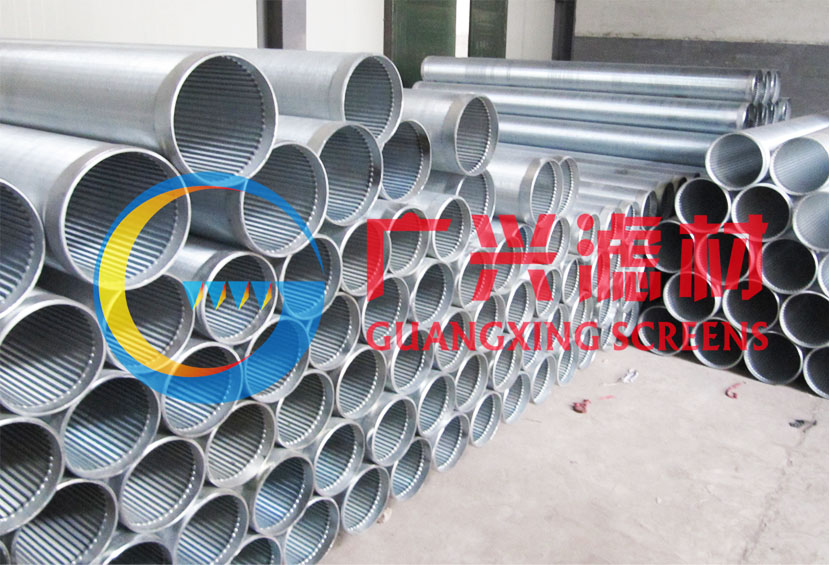

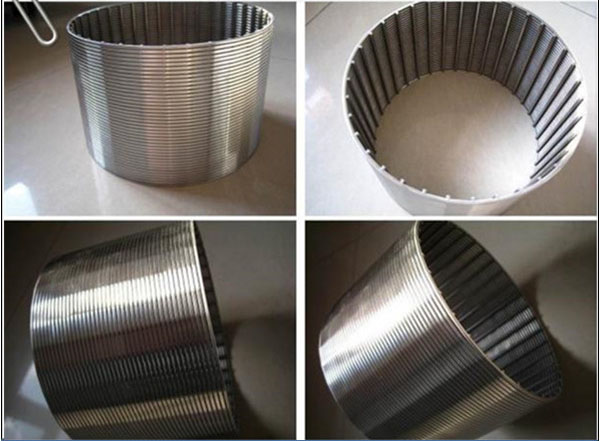

- Outer Screen: The outer layer, often made of stainless steel wire mesh, provides the primary filtration.

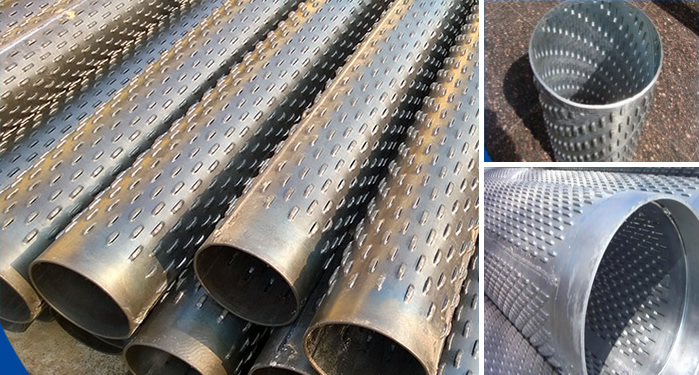

- Inner Pipe: The inner pipe, usually made of perforated stainless steel, offers structural support and secondary filtration.

- End Caps: These are welded to the ends of the pipe base screen to ensure a secure and leak-free connection.

Benefits of Stainless Steel Pipe Base Screens

Corrosion Resistance

Stainless steel is renowned for its excellent corrosion resistance, making it ideal for use in harsh environments, including offshore and onshore oil and gas fields.

High Strength and Durability

The inherent strength of stainless steel ensures that pipe base screens can withstand high pressures and mechanical stresses, providing long-lasting performance.

Efficient Filtration

Stainless steel wire mesh offers precise filtration, effectively preventing the ingress of unwanted particles while allowing the passage of fluids.

Versatility

Stainless steel pipe base screens are versatile and can be used in a wide range of applications, from water treatment to oil and gas extraction.

Easy Maintenance

The smooth surface of stainless steel makes it easy to clean and maintain, ensuring consistent performance over time.

Applications of Stainless Steel Pipe Base Screens

Oil and Gas Industry

In the oil and gas industry, stainless steel pipe base screens are used in well completions to prevent sand and other particles from entering the production tubing, ensuring the smooth flow of hydrocarbons.

Water Treatment

In water treatment plants, these screens are used to filter out debris and contaminants, ensuring the delivery of clean and safe water.

Filtration Systems

Stainless steel pipe base screens are integral components in various industrial filtration systems, providing efficient and reliable filtration of liquids and gases.

Geothermal Wells

In geothermal wells, these screens are used to prevent the ingress of sand and other particles, ensuring the efficient extraction of geothermal energy.

Technical Specifications

Material Grades

Stainless steel pipe base screens are available in various material grades, each offering specific properties to meet different application requirements.

- 304 Stainless Steel: Offers good corrosion resistance and strength, suitable for general applications.

- 316 Stainless Steel: Provides superior corrosion resistance, especially in chloride environments, making it ideal for marine and offshore applications.

- Duplex Stainless Steel: Combines high strength with excellent corrosion resistance, suitable for demanding applications.

Screen Types

Different types of screens are used to meet specific filtration requirements.

- Wedge Wire Screen: Features V-shaped wires welded to support rods, providing precise filtration and high open area.

- Perforated Screen: Made from perforated stainless steel sheets, offering high strength and durability.

- Mesh Screen: Constructed from woven stainless steel wire mesh, providing fine filtration.

Dimensions

Stainless steel pipe base screens are available in various dimensions to meet different application needs.

- Diameter: Typically ranges from 1 inch to 12 inches.

- Length: Standard lengths are 10 feet and 20 feet, but custom lengths can be manufactured.

- Slot Size: The slot size can be customized to meet specific filtration requirements, typically ranging from 0.1 mm to 3 mm.

Connection Methods

Various connection methods are used to ensure a secure and leak-free installation.

- Threaded Connections: Commonly used for smaller diameter screens, providing easy installation and removal.

- Welded Connections: Used for larger diameter screens, ensuring a strong and durable connection.

- Flanged Connections: Provide a secure and leak-free connection, suitable for high-pressure applications.

Manufacturing Process

Material Selection

The selection of high-quality stainless steel is the first step in the manufacturing process, ensuring the final product meets the required standards.

Forming and Welding

The stainless steel sheets or wires are formed into the desired shape and welded together using advanced welding techniques to ensure a strong and durable bond.

Slotting and Perforation

The slots or perforations are created using precision machining techniques, ensuring accurate and consistent filtration.

Surface Treatment

The surface of the pipe base screen is treated to enhance its corrosion resistance and durability, often involving processes such as passivation or electropolishing.

Quality Control

Rigorous quality control measures are implemented throughout the manufacturing process to ensure the final product meets the required specifications and standards.

Conclusion

Stainless steel pipe base screens are essential components in various industrial applications, offering high strength, excellent corrosion resistance, and efficient filtration capabilities. By understanding the design, benefits, applications, and technical specifications of these screens, industry professionals can make informed decisions to meet their specific needs. Whether used in the oil and gas industry, water treatment, or filtration systems, stainless steel pipe base screens provide reliable and long-lasting performance.

FAQ

1. What are the main advantages of stainless steel pipe base screens?

The main advantages include excellent corrosion resistance, high strength and durability, efficient filtration, versatility, and easy maintenance.

2. What materials are used in stainless steel pipe base screens?

Common materials include 304 stainless steel, 316 stainless steel, and duplex stainless steel, each offering specific properties to meet different application requirements.

3. What applications are suitable for stainless steel pipe base screens?

Suitable applications include the oil and gas industry, water treatment, industrial filtration systems, and geothermal wells.

4. How are stainless steel pipe base screens connected?

Common connection methods include threaded connections, welded connections, and flanged connections, ensuring secure and leak-free installation.

5. What are the common dimensions and slot sizes for stainless steel pipe base screens?

Common dimensions include diameters ranging from 1 inch to 12 inches, lengths of 10 feet and 20 feet, and slot sizes ranging from 0.1 mm to 3 mm.