A well screen is a filtering device that serves as the intake portion of wells constructed in unconsolidated or semi-consolidated aquifers. The screen permits water to enter the well from the saturated aquifer, prevents sediment from entering the well, and serves structurally to support the aquifer material. The importance of a proper well screen cannot be overemphasized when considering the efficiency of a well and the log-term cost to its owner.

Well screens are manufactured from a variety of materials and range from crude handmade contrivances to highly efficient and long-life models made on machines. The value of a screen depends on how effectively it contributes to the success of a well. Important screen criteria and functions include:

Criteria:

1. large percentage of open area

2. non clogging slots

3. resistant to corrosion

4. sufficient column and collapse strength Functions:

1. easily developed

2. minimal incrusting tendency

3. low head loss through the screen

4. control sand pumping in all types of aquifers

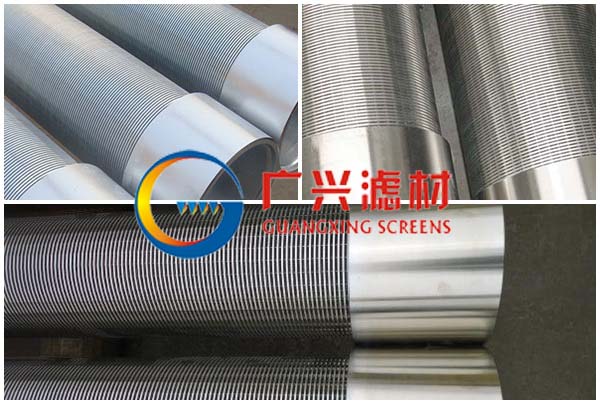

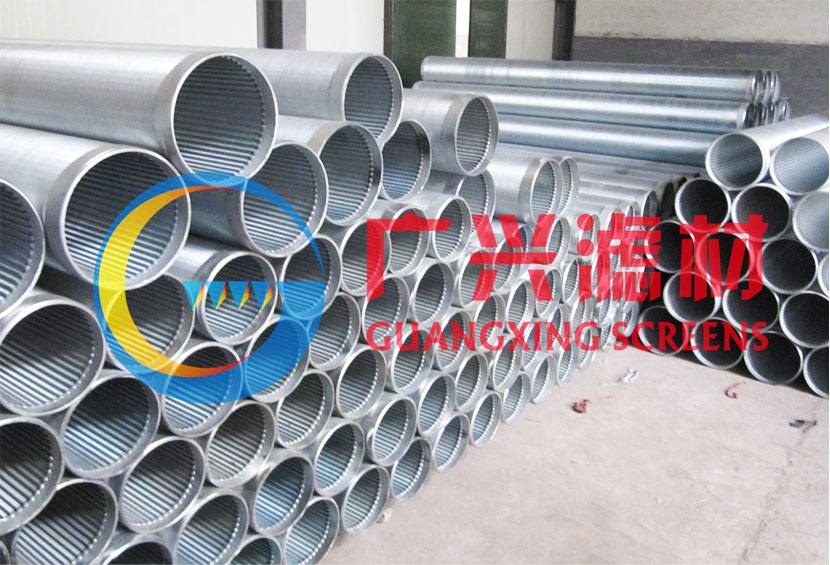

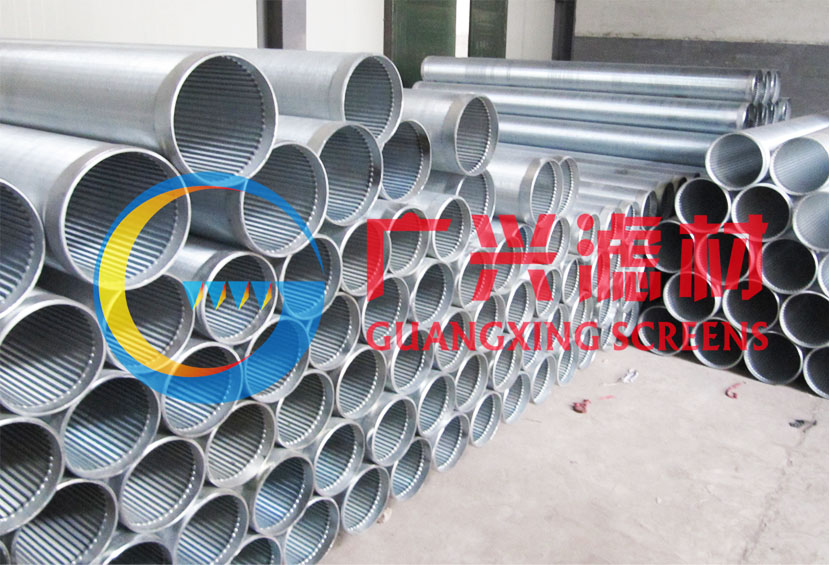

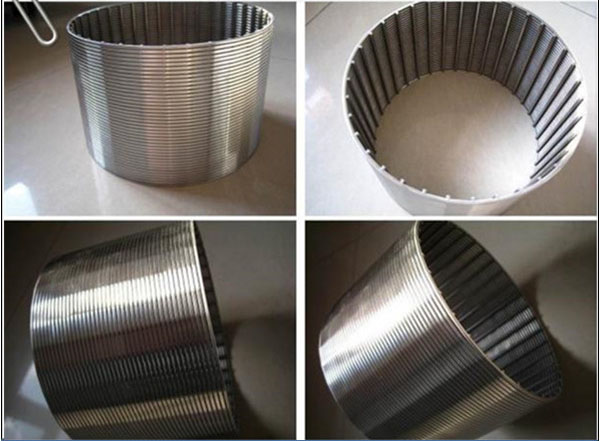

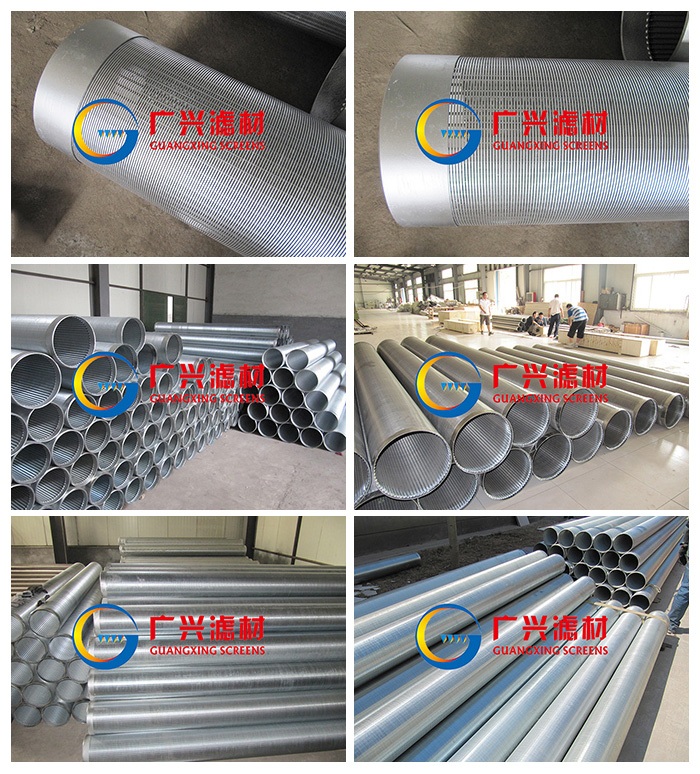

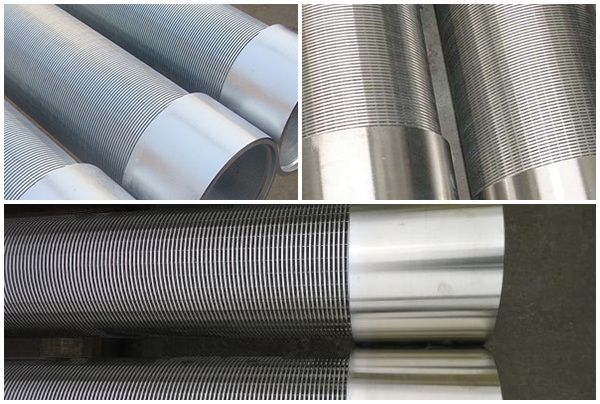

Continuous-Slot Screen

The continuous-slot screen is widely used throughout the world for water, oil, and gas wells, and is the dominant screen type used in the water well industry. It is made by winding rolled wire, triangular in cross section, around a circular array of longitudinal rods. The wire is attached to the rods by welding. Welded screens are commonly fabricated from stainless steel.

Slot openings are manufactured by spacing successive turns of the outer wire to produce the desired slot size. Slot openings have been designated by numbers which correspond to the width of the openings in thousandths of an inch. A No. 10 slot screen, for example.

Continuous-slot screens provide more intake area per unit area of screen surface than any other type. This type of screen has maximum open area. For best well efficiency, the percentage of open area in a screen should be the same as, or great than, the average porosity of the aquifer material. Water flows more freely through a screen with a large intake area compare to one with limited open area. The entrance velocity is low, therefore head loss for the screen is at a minimum, thus minimizing drawdown in the well.

| SLOT SIZE | 10 | 15 | 20 | 25 | 30 | 35 | 40 | 50 | 60 | 70 | 80* | 90* | 100* |

| SCREEN SIZE | |||||||||||||

| 4.5 In. I.D. | 600 | 580 | 560 | 540 | 520 | 500 | 480 | ||||||

| 6.5 In. I.D. | 415 | 400 | 385 | 370 | 360 | 345 | 330 | 315 | 300 | ||||

| 8.5 In. I.D. | 325 | 315 | 305 | 295 | 285 | 275 | 265 | 255 | 245 | ||||

| 10.5 In. I.D. | 260 | 253 | 246 | 239 | 232 | 225 | 218 | 211 | 204 | ||||

| 12 In. I.D. | 225 | 216 | 207 | 198 | 189 | 180 | 171 | 162 | 153 | ||||

| 16 In. I.D. | 185 | 165 | 145 | 125 | 105 | 85 | 65 | 45 | 25 |

The continuous-slot screen is widely used throughout the world for water,oil,and gas wells,and is the dominant screen type used in the water well industry. Continuous-slot screen is made by winding cold-rolled wire,approximately trianngular in cross section,around a circular array of the longitudinal rods. The wire is attached to the rods by welding, producing rigid one-piece units having high strength characteristics at minimum weights. Slot opening for continuous screens are manufactured by spacing successive turns of the outer wire to produce the desired slot size. All slots should be clean and free of burns and cuttings.