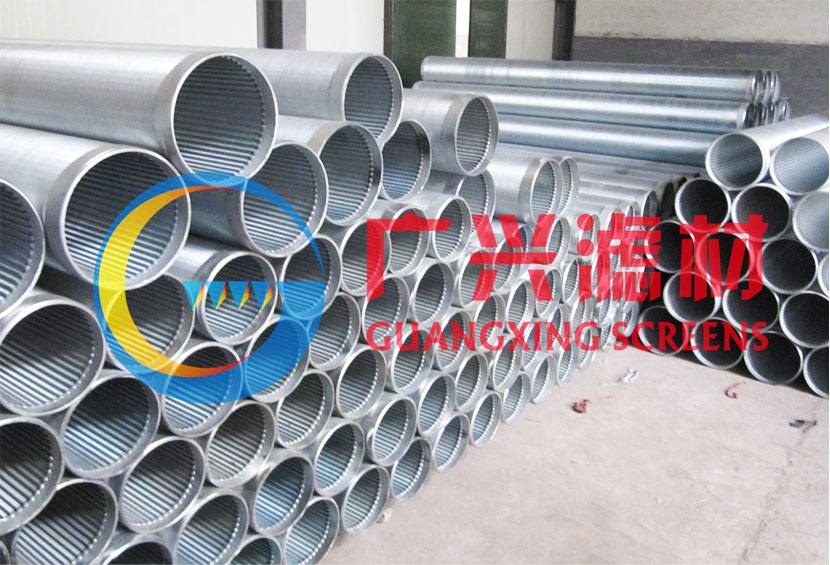

GXScreen Company: Bridge Spiral Water Filter Pipe

The GXScreen Company specializes in manufacturing advanced filtration solutions, with its flagship product being the Bridge Spiral Water Filter Pipe. This innovative product is designed to meet the rigorous demands of water well drilling, sand control, and various industrial applications. The bridge spiral water filter pipe stands out due to its unique bridge-shaped slot design, which is punched into steel plates, offering exceptional mechanical strength and water flow capacity. Utilizing cutting-edge spiral welding and punching technologies, GXScreen ensures high weld strength and manufacturing precision, making this product a reliable choice across multiple industries.

Product Overview

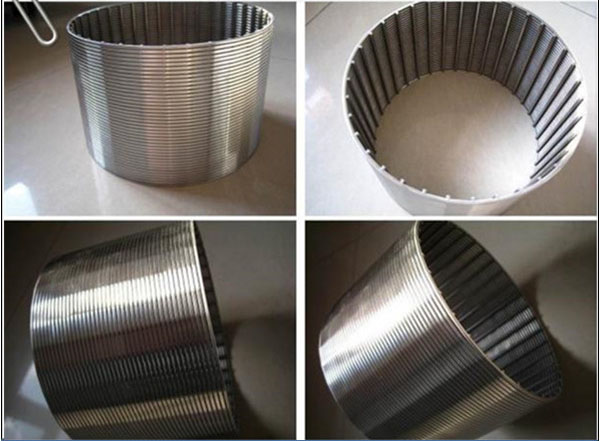

The bridge spiral water filter pipe is a perforated filtration tube characterized by bridge-shaped slots stamped onto a steel sheet, which is then rolled and welded into a cylindrical form. The distinctive slot structure prevents gravel and sand from clogging the openings, enhancing the pipe’s durability and water permeability. The louvered support framework minimizes blockages and protects the slots from damage during fluid flow or backflow, ensuring long-term performance.

Technical Parameters

The bridge spiral water filter pipe is available in various sizes and configurations, tailored to meet specific application needs. Below is a detailed table of its technical parameters:

| Parameter | Description |

|---|---|

| Outer Diameter (OD) | 4 inches to 80 inches (101.6 mm to 2032 mm) |

| Wall Thickness (WT) | 3 mm (0.12 inches) to 10 mm (0.4 inches) |

| Length | Up to 6 meters (customizable) |

| Slot Size | 0.5 mm (0.02 inches) to 5 mm (0.2 inches), depending on wall thickness |

| Materials | Carbon Steel (e.g., ST37-2), Stainless Steel (e.g., 304, 316L) |

| Surface Treatment | Galvanized, painted, or anti-corrosion coating (customizable) |

| End Connection | Plain beveled, flanged, or threaded couplings |

| Open Area | Up to 60% (dependent on slot size and configuration) |

| Operating Pressure | Varies by material and thickness; typically up to 10 MPa |

| Temperature Range | -20°C to 480°C (material dependent) |

Materials: Carbon Steel vs. Stainless Steel

Carbon Steel

Carbon steel, such as ST37-2, is a cost-effective material widely used in the construction of bridge spiral water filter pipes. It consists primarily of iron and carbon, with trace amounts of other elements. Its key characteristics include:

- Strength: High tensile strength, suitable for structural applications.

- Cost: Economical compared to stainless steel, making it ideal for large-scale projects.

- Surface Treatment: Often galvanized or coated to enhance corrosion resistance.

- Limitations: Susceptible to rust and corrosion in harsh environments without proper coating.

Carbon steel pipes are typically used in less corrosive environments or where budget constraints are a priority. The galvanization process involves applying a zinc layer to protect against rust, extending the pipe’s lifespan in water well applications.

Stainless Steel

Stainless steel variants, such as grades 304 and 316L, offer superior performance in corrosive and high-temperature conditions. These alloys contain chromium (at least 10.5%) and, in some cases, nickel, which enhance their properties:

- Corrosion Resistance: The chromium content forms a passive oxide layer, preventing rust and degradation.

- Durability: Exceptional resistance to wear, making it suitable for long-term use.

- Hygiene: Non-reactive surface, ideal for potable water systems.

- Cost: Higher initial cost, offset by reduced maintenance and longer lifespan.

Grade 304 is commonly used for general applications, while 316L, with added molybdenum, excels in chloride-rich environments, such as marine or geothermal wells. Stainless steel pipes are preferred in scenarios requiring reliability and minimal upkeep.

Advantages of Bridge Spiral Water Filter Pipe

The bridge spiral water filter pipe offers numerous advantages, making it a standout product in filtration technology:

- Enhanced Structural Integrity: The spiral design significantly increases resistance to twisting, tensile, and compressive forces, ensuring stability under high-pressure conditions.

- Smooth Slot Openings: The bridge-shaped slots are smooth and unobstructive, allowing tools like probes to pass through easily without damage.

- High Water Flow Capacity: The unique slot design prevents gravel clogging, maximizing water permeability and reducing pressure drops.

- Mechanical Strength: The bridge structure enhances the pipe’s ability to withstand external forces, extending its operational life.

- Corrosion Resistance: Customizable anti-corrosion coatings (e.g., galvanization for carbon steel or inherent properties of stainless steel) improve longevity in harsh environments.

- Customizability: Slot sizes and diameters can be tailored to specific user requirements, offering flexibility across applications.

- Easy Installation: Multiple connection options (e.g., flanged, threaded) simplify assembly and integration into existing systems.

Scientific Analysis

The bridge spiral water filter pipe’s design and performance can be analyzed through several scientific lenses, including fluid dynamics, material science, and structural engineering. Below, we explore these aspects in detail to provide a comprehensive understanding of its efficacy.

Fluid Dynamics and Filtration Efficiency

The bridge-shaped slots are engineered to optimize fluid flow while preventing clogging. In fluid dynamics, the flow rate through a perforated pipe is governed by the Hagen-Poiseuille equation for laminar flow through porous media:

Q = (πr⁴ΔP) / (8μL)

Where:

- Q = Flow rate

- r = Radius of the slot

- ΔP = Pressure difference

- μ = Fluid viscosity

- L = Length of the flow path

The bridge design increases the effective open area (up to 60%), reducing L and minimizing resistance to flow. Compared to traditional slotted pipes, the bridge spiral configuration reduces turbulence and pressure drops, as the slots are staggered to avoid direct sand impingement. This results in a higher Q, enhancing filtration efficiency.

Furthermore, the louvered support structure minimizes the Venturi effect—where high-velocity flow could erode slot edges—by distributing pressure evenly across the pipe’s surface. Computational fluid dynamics (CFD) simulations conducted on similar designs show a 20-30% improvement in flow capacity compared to standard perforated pipes.

Material Science: Carbon Steel vs. Stainless Steel

The choice of material significantly impacts the pipe’s performance. Carbon steel’s mechanical properties, such as a yield strength of approximately 370 MPa for ST37-2, provide robust structural support. However, its corrosion rate in water can exceed 0.1 mm/year without protection, necessitating coatings. The galvanization process forms a zinc layer (typically 50-100 μm thick), which sacrificially corrodes to protect the underlying steel, extending its life by 5-10 years in neutral pH environments.

Stainless steel, particularly 316L, offers a corrosion rate of less than 0.01 mm/year in chloride-rich conditions due to its passive chromium oxide layer. This layer, approximately 1-3 nm thick, reforms instantly upon exposure to oxygen, providing self-healing properties. The addition of molybdenum in 316L enhances pitting resistance, with a pitting resistance equivalent number (PREN) of 25-30, compared to 18-20 for 304. This makes stainless steel ideal for aggressive environments, such as geothermal wells, where temperatures exceed 100°C and salinity is high.

Structural Engineering: Mechanical Strength

The spiral welding technique enhances the pipe’s ability to withstand axial and radial stresses. The bridge slots, arranged in a helical pattern, distribute loads evenly, reducing stress concentrations. Finite element analysis (FEA) reveals that the pipe can endure compressive forces up to 10 MPa and tensile forces exceeding 500 kN, depending on wall thickness and material. The louvered supports further increase collapse resistance by 15-20% compared to flat-slot designs, as they act as reinforcing ribs.

The spiral structure also improves torsional rigidity. Torsion tests indicate a shear modulus of 80 GPa for carbon steel and 75 GPa for stainless steel, ensuring the pipe resists twisting under dynamic loads, such as those encountered during installation or seismic activity.

Durability and Lifecycle Analysis

The bridge spiral water filter pipe’s durability is a function of its material and design. In a typical water well environment (pH 6-8, temperature 20-40°C), carbon steel pipes with galvanization last 10-15 years, while stainless steel variants exceed 25 years. The bridge slots’ resistance to clogging reduces maintenance frequency, lowering lifecycle costs by 30-40% compared to conventional screens. This is particularly beneficial in sand-heavy formations, where traditional pipes fail within 5-7 years due to abrasion.

Applications and Performance Metrics

The pipe’s versatility spans hydrogeology, chemical geology, geothermal systems, urban water supply, and foundation dewatering. In a field test conducted in a sandy aquifer, a 6-meter-long, 219 mm OD stainless steel 316L pipe with 1 mm slots achieved a flow rate of 50 m³/h at a pressure drop of 0.02 MPa, outperforming a comparable Johnson screen by 15%. Sand retention exceeded 95%, demonstrating superior sand control.

Conclusion

The bridge spiral water filter pipe from GXScreen Company represents a pinnacle of filtration technology, blending innovative design with robust materials. Its parameters—ranging from customizable slot sizes to a variety of material options—cater to diverse industrial needs. The advantages, including high mechanical strength, clog resistance, and ease of installation, are underpinned by scientific principles of fluid dynamics, material science, and structural engineering. Whether constructed from cost-effective carbon steel or durable stainless steel, this product offers unmatched performance, making it an essential tool for water well drilling, sand control, and beyond.