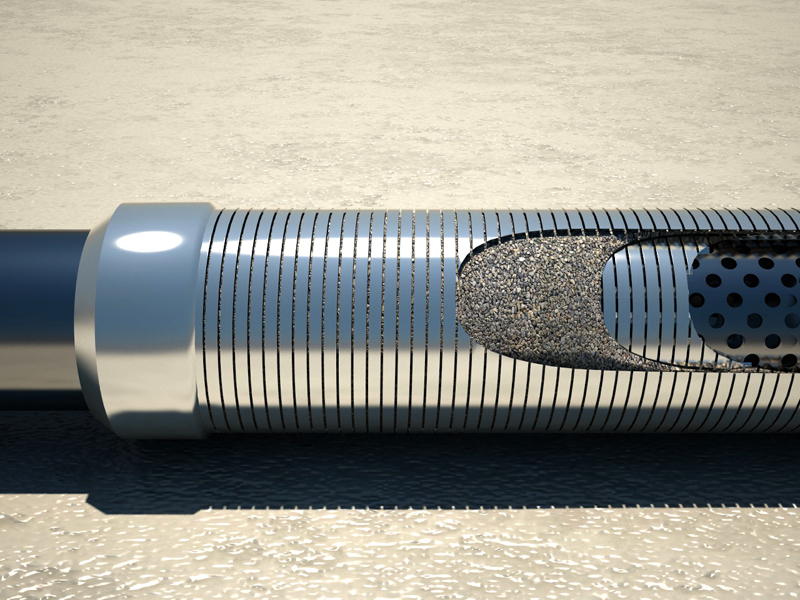

Slotted Pipe is a robust and effective device for sand control in the horizontal completion wells of SAGD and other thermal heavy oil recovery. Its excellent properties in withstanding installation loads and operation loads make it the premier choice for SAGD.

GUANGXING precision slotted pipes are manufactured by CNC controlled slotting machines or laser machine. Base pipe are per API casing or tubing specification with diameters from 1.5 inch to 18 inch. Pipe lengths of any diameter are available. All slotted joints are deburred internally, cleaned and drift tested according to API standards. Every slot is visually inspected and cleaned of burr material. All threads and couplings are thoroughly cleaned and lubricated. Slotted Pipe are suitable for gravel packed completions or stand-alone completion where grain size is large.

Slotted pipes is a robust and cost-effective solution providing bore hole stability and sand control in long horizontal completions and low productivity wells.

Staggered slotted liner sample in staggered patternStaggered slotted liner sample in staggered patternStaggered Slotted Pipe fabricated by advanced laser cutting process

Slotted liner patternsThree slotted liner patterns -straight, staggered and gang – are supplied. Each has its own characteristics.

Slotted liner in straight line pattern Staggered pattern with offset Slotted liner in gang pattern or multiple staggered patternStraight pattern Staggered pattern Gang patternSlotted geometrySlotted shapes are classified into two types: straight cut slot and keystone slot. Compared with straight slot, keystone slot has higher resistance against plugging for its inter size is larger than the surface size. Once the sand entering the keystone slot, the possibility of clogging will drop sharply.

Slotted liner patterns

Three slot patterns are designed for different characteristics (shown below). Compared to staggered and straight slot patterns, gang slot pattern has superiorities over installation torque-loading capacity and substantially improves the liner’s resistance to lateral bucking and collapse pressures.

| Slotted Liner Patterns | ||

| Staggered Slotted Liner | Gang Slotted Liner | Straight slotted liner |

|

|

|

| Staggered slots features alternate slot evenly spaced around the circumference with offset. | Gang slots feature multiple slots evenly spaced around circumference in a staggered pattern. | Straight slotted liner features slot columns spaced evenly around the circumference without offset. |

Normally specifications of slotted pipe

*length: up to15m

*outside diameter: 50~200mm

*slot width: 0.10~4 mm ±0.03mm

*slot number: as per customer’s requirement

*slot space: as per customer’s requirement

*slot patterns & shapes: please refer to the right drawing, more other options available, please contact us directly

Product specification

| Required slot per ft. for 3% open area | |||||

| Slot Width (mm) | Slot Width (inch) | 3.5″ Liner | 4.5″ Liner | 5.5″ Liner | 7″ Liner |

| 0.38 | 0.015 | 176 | 228 | 276 | 352 |

| 0.45 | 0.018 | 148 | 188 | 232 | 296 |

| 0.5 | 0.020 | 132 | 172 | 208 | 264 |

| 0.63 | 0.025 | 108 | 136 | 168 | 212 |

| 0.7 | 0.028 | 96 | 124 | 148 | 188 |

| 1 | 0.038 | 52 | 68 | 84 | 104 |

| 1.5 | 0.058 | 36 | 44 | 56 | 68 |

| 3 | 0.125 | 16 | 24 | 28 | 32 |

| 6 | 0.250 | 8 | 12 | 16 | 16 |

How many holes needed to achieve a certain open area?

N = 12*3.14*D*C / 100*W*L

N = the number of slots per foot.

D = Outside diameter of the liner (in inches).

C = Open area percentage.

W = selected slot width (in inches).

L = Length of slot (inches).

Slotted ( or preperforated ) liner completions are by far the most common completion run in horizontal wells. The primary purpose of the slotted-liner is preventing hole collapse in formations that may tend to cave in after being drilled, or as the formation pressure depletes.

This paper discusses particular aspects critical to designing a successful slotted-liner completion for compact sandstone reservoirs in Mexico. Three examples are given of applications of these special completions in these horizontal wells. Introduction

Oil and gas wells are drilled horizontally for a variety of reasons, chiefly to improve production without drilling multiple vertical wells and to prevent water or gas coning at specific conditions. Benefits of horizontal drilling are well documented and without exaggeration, horizontal hole technology can be classified as the hottest technical issue of today.

As discussed in previous literature, two basic types of horizontal completions exist: the continuos entry and the discreet flow entry. Open hole and slotted-liner completions fall into the category of continuos flow entry completions and are characterized by the fact that they offer little or no provisions for zone isolation.

An open hole completion is the most basic and is the simplest completion method. Open hole ( Fig. 1 ) completions can be effective only where reservoir rock has enough integrity to prevent wall collapse or sloughing from blocking product flow to the wellhead. Success of this completion style depends also on existence of natural fractures and permeability in the reservoir, since stimulation of drain holes is not particularly effective because isolation of intervals for treatment is unlikely to be feasible.

These wells are cemented through the vertical portion of the hole and just into the producing interval. Production may be from natural forces in the reservoir, or tubing may be run through the vertical portion and into the pay zone to allow for removal by pump.