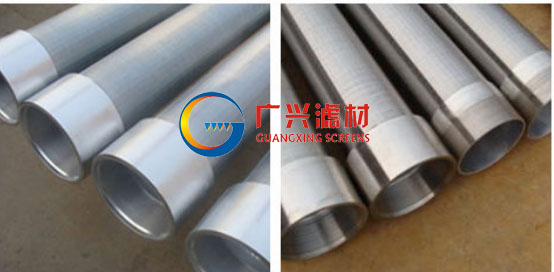

Well screen(water filter)

The continuous-slot well screen is widely used throughout the world for water, oil, and gas wells, and is the dominant screen type used in the water well industry. Aokai Continuous-Slot Well Screen is made by winding cold-rolled wire, approximately triangular in cross section, around a circular array of the longitudinal rods. The wire is attached to the rods by welding, producing rigid one-piece units having high strength chwater filteraracteristics at minimum weights. Slot opening for continuous-slot screens are manufactured by spacing successive turns of the outer wire to produce the desired slot size. All slots should be clean and free of burrs and cuttings.Each slot opening between adjacent wires is V-shaped, from the special shape of wire used to form the screen surface. The V-shaped openings designed to be nonclogging, are narrowest at the outer face and widen inwardly; they allow;

1. Production process continuity: V-shaped profile wires creating slots which enlarge inwardly and therefore avoid clogging and minimize downtime.

2. Low maintenance costs: Separation at the screen surface which can easily cleaned by scraping or back washing.

3. Maximum process output: Precise and continuous slot openings resulting in accurate separation without loss off media.

4. Low operational costs: Large open area with an effective flow, high yield and a low pressure drop (dP)

5. Long live: Welded at each intersection creating a strong and durable screen.

6. Reduced installation costs: supporting constructions eliminating costly support media and enabling a maximum flexibility in the design of components.

7. Chemical and thermal resistant: A variety of corrosion resistant stainless steel materials and many exotic alloys suitable for high temperatures and pressures.Each slot opening between adjacent wires is V-shaped, resulting from the special shape of the wire used to form the screen surface. The V-shaped opeings, designed to be nonclogging, are narrowest at the outer face and widen inwardly.Continuous-slot screens provide more intake area per unit area of screen surface than any other type. For any given slot size, this type of screen has maximum open area.

| Screen Size | Inside Diameter | Outside Diameter | OD of Female Threaded End | ||||

| in | mm | In | mm | in | mm | In | mm |

| 2 | 51 | 2 | 51 | 25/8 | 67 | 23/4 | 70 |

| 3 | 76 | 3 | 76 | 35/8 | 92 | 33/4 | 95 |

| 4 | 102 | 4 | 102 | 45/8 | 117 | 43/4 | 121 |

| 5 | 127 | 5 | 127 | 55/8 | 143 | 53/4 | 146 |

| 6 | 152 | 6 | 152 | 65/8 | 168 | 7 | 178 |

| 8 | 203 | 8 | 203 | 85/8 | 219 | 91/4 | 235 |

| 10 | 254 | 10 | 254 | 103/4 | 273 | 113/8 | 289 |

| 12 | 305 | 12 | 305 | 123/4 | 324 | 133/8 | 340 |

| 14 | 356 | 131/8 | 333 | 14 | 356 | — | — |

| 16 | 406 | 15 | 381 | 16 | 406 | — | — |

| 20 | 508 | 18 3/4 | 476 | 20 | 508 | — | — |

| PROFILE WIRE | ||||||||

| WIDTH(mm) | 1.50 | 1.50 | 2.30 | 2.30 | 1.80 | 3.00 | 3.70 | 3.30 |

| HEIGHT(mm) | 2.20 | 2.50 | 2.70 | 3.60 | 4.30 | 4.70 | 5.60 | 6.30 |

| SUPPORT ROD | ROUND |

|||||

| WIDTH(mm) | 2.30 | 2.30 | 3.00 | 3.70 | 3.30 | Ø2.5–Ø5mm |

| HEIGHT(mm) | 2.70 | 3.60 | 4.70 | 5.60 | 6.30 | —- |

Slot size (mm):0.10,0.15,0.2,0.25,0.30-3,also achieved upon customer request.

Open area up to 60%.

Material : Low Carbon ,Low Carbon Galvanized steel (LCG),, steel treated with plastic spraying,Stainless Steel

Steel( 304,etc.)

Lengths up to 6 meters.

Diameter ranging from 25 mm to800 mm

End Connection :Plain beveled ends for butt welding or threaded.

Johnson Well Screen water filter Pipe, wire and is supported by the V-shaped bar around, each crosspoint connection with welding mode, solid structure, good mechanical properties. V-shaped cross-section to avoid clogging, while ensuring the smooth flow of water. Continuous gap greater over the water area, while reducing groundwater infiltration rate, to avoid sand in the larger pressure into the tube, there is a better filter sand of the slit can also vary depending on geology.

Material: common steel blackboard, galvanized plate, stainless steel, copper, nickel plate, aluminum, resin panels.

Manufacturing: stamping by the punch through the die, the outer protective sheath may also spiral welded. Filter tubes may be made of stainless steel 304,316,316L, multilayer sand filtration kits and protection kits can be produced according to user needs.

Features:

1, multi-layer anti-sand filtration kits sand with efficient performance, better able to block the formation sand to meet the underground sand.

2, the filter pore uniform, high permeability and anti-blocking properties.

3, filter area, flow resistance is small.

4, stainless steel excellent corrosion resistance, acid, alkali, salt corrosion, can be adapted to the special requirements of wells, crevice corrosion and will not become bigger.

5, the multilayer structure welding can filter hole stability, resistance to deformation ability.

specification:

| List of major technical indicators Johnson tube | |||

| diameer (mm) | length (mm) | slit (mm) | Type of jiont (mm) |

| 62、75、90、102、116、128 | 500、1000、1500、2000 | 0.1、0.15、0.2、0.25、0.3、0.35、0.4 | short pipe nipple yin and yang |

| Description | in addition to the above specifications can be fabricated with diameters from φ35mm-φ300mm, length from 100mm-250mm series of screens based on user requirements | ||