Laser Slotted Casing Pipes: A Comprehensive Guide

Introduction

Laser slotted casing pipes are an essential component in well construction, particularly in water wells, oil and gas wells, and geothermal wells. These pipes are designed with precise slots or perforations that allow water, oil, or gas to flow into the well while preventing the entry of sand, gravel, and other debris. The use of laser technology in creating these slots ensures precision, uniformity, and high-performance filtration, making laser slotted casing pipes a popular choice in well completion.

This article will provide a detailed overview of laser slotted casing pipes, including their design, manufacturing process, advantages, applications, and selection criteria.

Table of Contents

- What Are Laser Slotted Casing Pipes?

- How Are Laser Slotted Casing Pipes Manufactured?

- Advantages of Laser Slotted Casing Pipes

- Applications of Laser Slotted Casing Pipes

- Types of Laser Slotted Casing Pipes

- How to Select the Right Laser Slotted Casing Pipe

- Installation and Maintenance

- Frequently Asked Questions (FAQ)

- Conclusion

What Are Laser Slotted Casing Pipes? {#what-are-laser-slotted-casing-pipes}

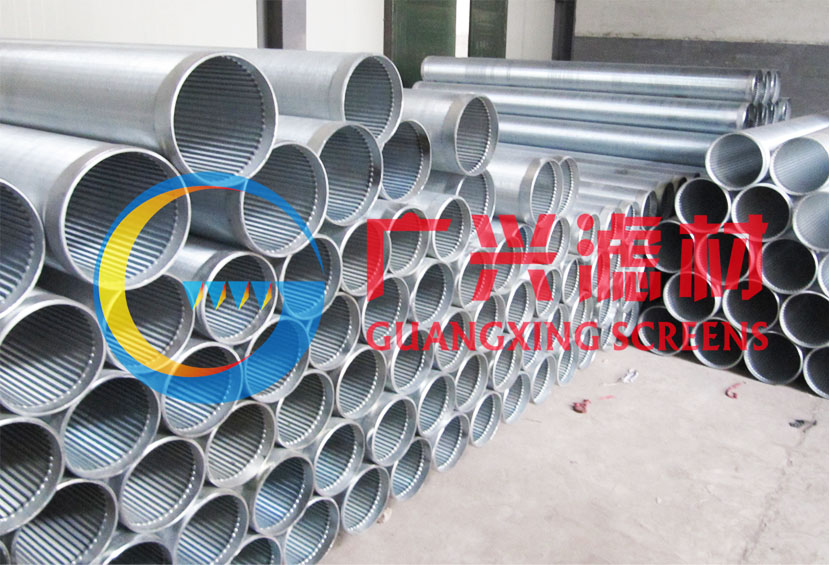

Laser slotted casing pipes are steel or stainless steel pipes that feature precision-cut slots created using laser technology. These slots allow fluids to enter the well while filtering out sand, gravel, and other unwanted materials. The laser cutting process ensures that the slots are uniform in size and shape, providing consistent filtration and high flow rates.

The primary purpose of a slotted casing pipe is to act as a filtering mechanism in the well, ensuring that only clean fluids enter the wellbore while preventing the entry of sediments that could clog the well or damage the pumping equipment.

Specifications of OASIS Slotted Casing Pipes

the slot can be up to 0.10mm

the cutting thickness of carbon steel is up to 20mm

the cutting thickness of stainless steel is up to 10mm

| API Std. Casing | ID (mm) |

Length (mm) |

Slot Length (mm) |

Slot No./m |

Slot Width (mm) |

Slot Tolerance |

Valid Filter Area (cm2/m) |

Max Strength (kn) |

||

| 60.32 | 5 | 6.84 | 50.3 | 3 | 80 | 200 | 0.3 | ±50 | 48 | 512.54 |

| 73.02 | 5.5 | 9.15 | 62 | 3 | 80 | 240 | 0.3 | ±50 | 57.6 | 688.55 |

| 88.9 | 6.5 | 13.22 | 75.9 | 3 | 80 | 280 | 0.3 | ±50 | 67.2 | 995.1 |

| 101.6 | 6.5 | 15.22 | 88.6 | 3 | 80 | 300 | 0.3 | ±50 | 72 | 1151.2 |

| 114.3 | 7 | 18.47 | 100.3 | 10 | 80 | 320 | 0.3 | ±50 | 76.8 | 1400.4 |

| 127 | 7.52 | 22.13 | 112 | 10 | 80 | 340 | 0.3 | ±50 | 81.6 | 1673.8 |

| 139.7 | 7.72 | 25.11 | 124.3 | 10 | 80 | 360 | 0.3 | ±50 | 86.4 | 1900.2 |

| 9.17 | 29.48 | 121.4 | 10 | 80 | 360 | 0.3 | ±50 | 86.4 | 2232.4 | |

| 168.3 | 8.94 | 35.09 | 150.4 | 10 | 80 | 400 | 0.3 | ±50 | 96 | 2672.95 |

| 177.8 | 8.05 | 33.68 | 161.7 | 10 | 80 | 440 | 0.3 | ±50 | 105.6 | 2559.2 |

| 9.19 | 38.19 | 159.4 | 10 | 80 | 440 | 0.3 | ±50 | 105.6 | 2940.7 | |

How Are Laser Slotted Casing Pipes Manufactured? {#how-are-laser-slotted-casing-pipes-manufactured}

The manufacturing process for laser slotted casing pipes involves the use of high-precision laser cutting machines to create slots in a steel or stainless steel pipe. The process can be broken down into the following steps:

1. Pipe Selection

The first step is selecting the appropriate pipe material based on the application. Common materials include carbon steel, stainless steel, and alloy steel. The pipe’s diameter, wall thickness, and length are chosen according to the well’s design specifications.

2. Laser Cutting

Once the pipe is selected, it is placed in a laser cutting machine. The laser beam is focused on the pipe’s surface, where it precisely cuts slots or perforations into the pipe. The laser cutting process allows for high precision, ensuring that each slot is uniform in size and shape.

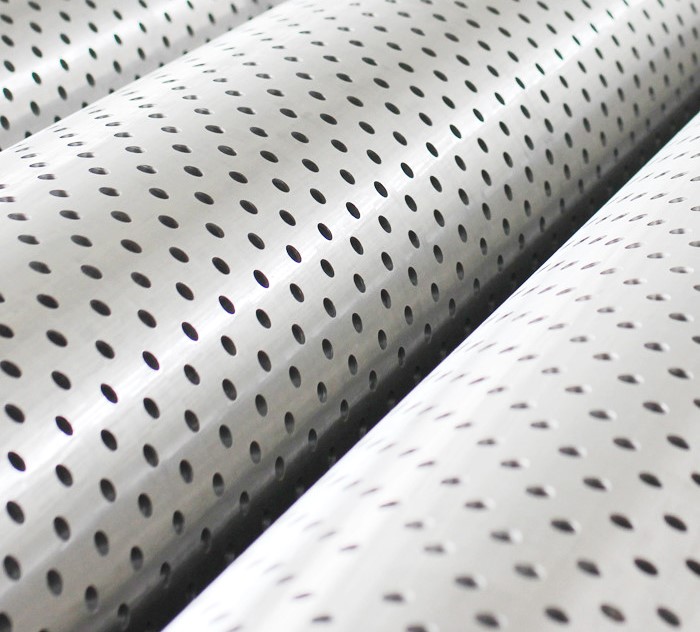

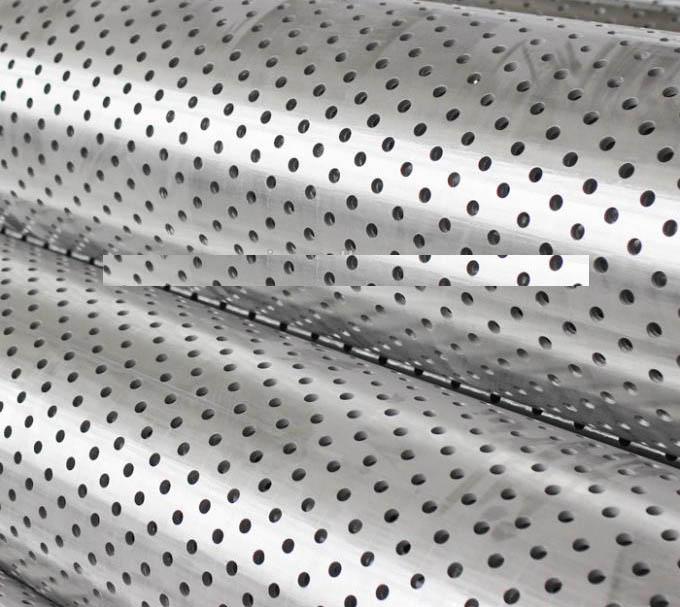

3. Slot Design

The slot pattern and slot size are determined based on the grain size of the surrounding formation and the desired flow rate. The slots can be cut in various patterns, such as straight slots, spiral slots, or staggered slots, to optimize the pipe’s filtration capacity and structural integrity.

4. Quality Control

After the slots are cut, the pipe undergoes quality control inspections to ensure that the slots meet the required specifications. This includes checking the slot width, slot length, and slot spacing to ensure that they are within the specified tolerances.

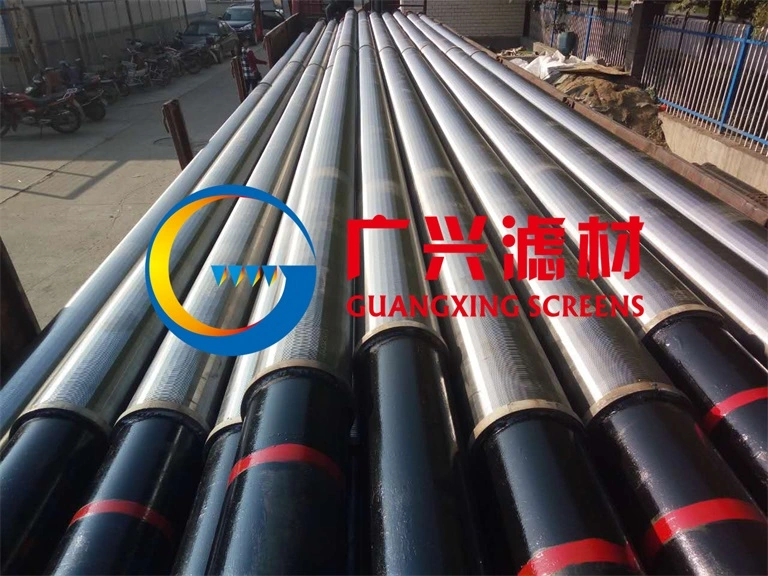

5. Surface Treatment

In some cases, the pipe may undergo surface treatment to improve its corrosion resistance. This can include processes such as galvanizing, coating, or passivation (for stainless steel pipes).

Advantages of Laser Slotted Casing Pipes {#advantages-of-laser-slotted-casing-pipes}

Laser slotted casing pipes offer several advantages over other types of well screens and perforated pipes. These advantages include:

1. Precision and Uniformity

The use of laser technology ensures that the slots are cut with high precision, resulting in uniform slot sizes and consistent filtration. This precision reduces the risk of clogging and ensures that the well operates efficiently.

2. High Flow Rates

The precisely engineered slots in laser slotted casing pipes allow for high flow rates while preventing the entry of sand and gravel. This ensures that the well can produce large volumes of fluid without becoming clogged.

3. Customizable Slot Patterns

Laser slotted casing pipes can be customized with various slot patterns to suit the specific geological conditions of the well. This allows for optimized filtration and flow control, improving the well’s overall performance.

4. Durability and Strength

Laser slotted casing pipes are made from high-strength materials such as carbon steel or stainless steel, ensuring that they can withstand the high pressures and mechanical stresses encountered in deep wells. The laser cutting process also minimizes the risk of structural weakening, ensuring the pipe’s integrity.

5. Corrosion Resistance

When made from stainless steel or treated with corrosion-resistant coatings, laser slotted casing pipes offer excellent resistance to corrosion in aggressive environments such as saltwater wells or geothermal wells.

6. Cost-Effective

While laser slotted casing pipes may have a higher initial cost compared to other types of well screens, their long service life, high performance, and low maintenance requirements make them a cost-effective solution in the long run.

Applications of Laser Slotted Casing Pipes {#applications-of-laser-slotted-casing-pipes}

Laser slotted casing pipes are used in a variety of industries and applications where well filtration is critical. Some common applications include:

1. Water Wells

Laser slotted casing pipes are widely used in municipal water wells, irrigation wells, and industrial water supply wells. The precise slots allow for high flow rates while preventing the entry of sand and sediment, ensuring a reliable supply of clean water.

2. Oil and Gas Wells

In the oil and gas industry, laser slotted casing pipes are used to filter out sand and gravel while allowing oil, gas, or water to flow into the well. The pipes are designed to withstand the high pressures and corrosive environments typically found in oil and gas fields.

3. Geothermal Wells

Laser slotted casing pipes are used in geothermal wells to filter out sediments while allowing geothermal fluids to flow into the well. The pipes must be able to withstand the high temperatures and corrosive conditions found in geothermal environments.

4. Environmental Monitoring Wells

In environmental monitoring wells, laser slotted casing pipes are used to sample groundwater and monitor contamination levels. The precise slots ensure that the samples are free from sediment contamination, providing accurate data for environmental assessments.

5. Mining and Dewatering Wells

Laser slotted casing pipes are also used in mining and dewatering wells to manage groundwater levels and prevent flooding in mining operations. The pipes allow for efficient water extraction while preventing the entry of debris.

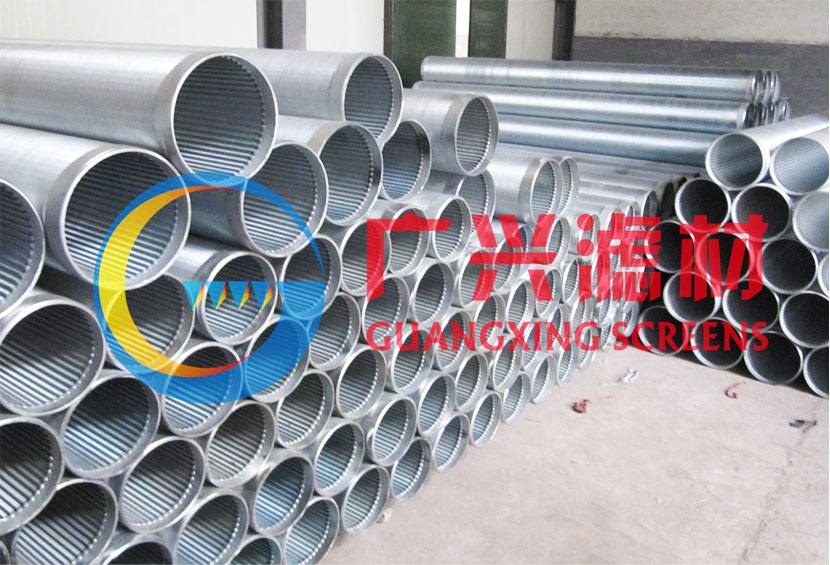

Types of Laser Slotted Casing Pipes {#types-of-laser-slotted-casing-pipes}

Laser slotted casing pipes come in a variety of slot patterns and configurations to suit different well conditions. Some common types include:

1. Straight Slot Casing Pipes

These pipes feature straight slots that run parallel to the length of the pipe. Straight slot casing pipes are ideal for wells with uniform grain sizes and moderate flow rates.

2. Spiral Slot Casing Pipes

Spiral slot casing pipes have slots that are cut in a spiral pattern around the pipe. This design provides a larger open area and allows for higher flow rates, making it suitable for wells with high production demands.

3. Staggered Slot Casing Pipes

In staggered slot casing pipes, the slots are arranged in a staggered pattern around the pipe. This design provides even distribution of fluid flow and reduces the risk of clogging.

4. Custom Slot Patterns

Laser slotted casing pipes can be customized with unique slot patterns to meet the specific needs of the well. This allows for optimized filtration and flow control based on the geological conditions of the well.

How to Select the Right Laser Slotted Casing Pipe {#how-to-select-the-right-laser-slotted-casing-pipe}

Selecting the right laser slotted casing pipe for your well requires careful consideration of several factors, including:

1. Slot Size

The slot size should be based on the grain size of the surrounding formation. A sieve analysis can help determine the appropriate slot size to ensure efficient filtration and prevent clogging.

2. Material Selection

The choice of material depends on the corrosiveness of the well environment. Stainless steel is recommended for wells with aggressive groundwater or high chloride content, while carbon steel may be suitable for less corrosive environments.

3. Well Depth and Pressure

Deeper wells are subject to higher pressures, so it is important to choose a casing pipe with sufficient strength and collapse resistance. Thicker-walled pipes or high-strength materials may be required for deep wells.

4. Flow Rate Requirements

The open area of the slotted casing pipe will affect the flow rate of the well. Spiral slot or staggered slot designs offer higher open areas and are ideal for wells with high flow rate requirements.

5. Corrosion Resistance

If the well is located in a corrosive environment, such as near the coast or in a geothermal field, it is important to choose a casing pipe with high corrosion resistance. 316 stainless steel or duplex stainless steel are recommended for such environments.

Installation and Maintenance {#installation-and-maintenance}

Installation

Proper installation of laser slotted casing pipes is critical to ensuring their performance and longevity. The casing pipe should be installed at the correct depth, with the slots oriented to maximize fluid flow from the aquifer or reservoir. In some cases, a gravel pack may be used around the casing to enhance filtration and prevent clogging.

Maintenance

Regular inspection and maintenance of the slotted casing pipe are important to ensure optimal performance. Over time, the slots may become clogged with sediment or biofilm, reducing the flow rate. Jetting, brushing, or chemical treatments can be used to clean the slots and restore their functionality.

Frequently Asked Questions (FAQ) {#faq}

1. What is the purpose of a slotted casing pipe?

A slotted casing pipe is used to filter out sand, gravel, and other sediments while allowing water, oil, or gas to flow into the well. It helps prevent clogging and protects the pumping equipment from damage.

2. Why is laser cutting used for slotted casing pipes?

Laser cutting is used for slotted casing pipes because it provides high precision, ensuring that the slots are uniform in size and shape. This precision improves filtration efficiency and flow control.

3. How do I choose the right slot size for my slotted casing pipe?

The slot size should be based on the grain size of the surrounding formation. A sieve analysis of the formation material can help determine the appropriate slot size to ensure efficient filtration and flow.

4. Can laser slotted casing pipes be used in saltwater wells?

Yes, stainless steel laser slotted casing pipes, particularly those made from 316 stainless steel, are ideal for use in saltwater wells due to their high resistance to chloride corrosion.

5. How often should a slotted casing pipe be cleaned?

The frequency of cleaning depends on the well conditions and the amount of sediment in the water. Regular inspections can help determine when cleaning is necessary.

Conclusion {#conclusion}

Laser slotted casing pipes are a critical component in well construction, providing precise filtration and high flow rates while preventing the entry of sediments that could clog the well or damage the pumping equipment. The use of laser technology ensures that the slots are cut with high precision, resulting in uniform slot sizes and consistent performance.

Whether used in water wells, oil and gas wells, or geothermal wells, laser slotted casing pipes offer durability, corrosion resistance, and customizability, making them a reliable and cost-effective solution for well completion. By selecting the right slot size, material, and design, well operators can ensure that their wells operate efficiently and have a long service life.