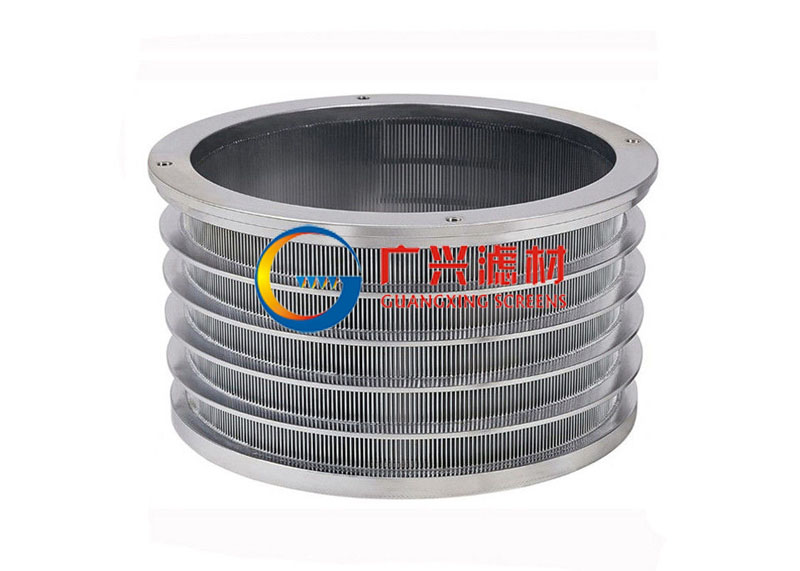

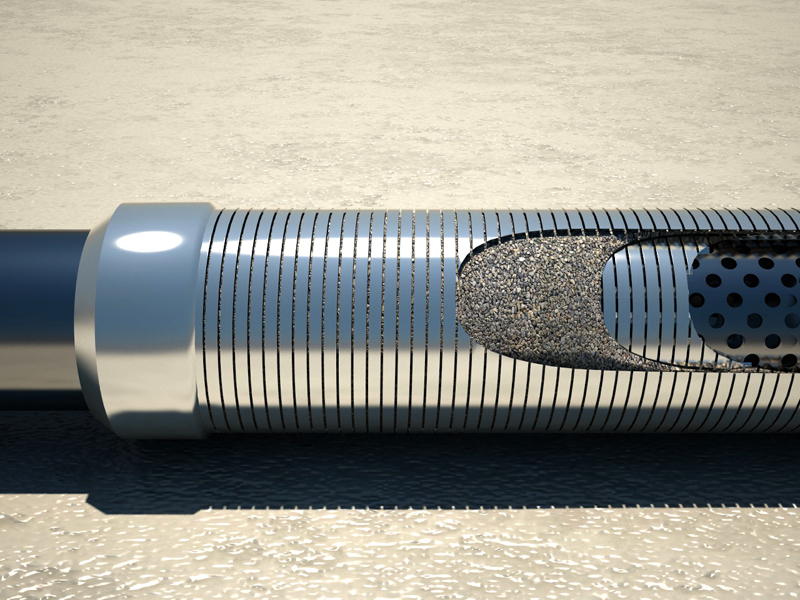

The consecutive slot have more open area, and it can reduce the speed of the water entering to avoid the sand entering the Water Well Screens under the great pressure, so it can filter sand better. Meanwhile, the slot of Water Well Screens can change according to the real condition of the earth.

Specifications of SS304L Wedge Wire Continuous Slot Water Well Screens:

1.Material: stainless steel (304,304L,316,316L etc.)

2.Diameter: 244.5mm or from 38-1500mm

3.Slot Size (mm):0.3, 0.5, 0.75, 1 or as per customers’ requirement

4.Unit length up to 6m, 5.8m fit for the container

5.Open area 33%

6.End Connection:Welding (beveled end), thread coupling(STC,LTC,BTC) or flange

7.Surface treatment:Galvanized, painted, polish, pickling & passivation,etc.

8.Packing:Bubble bag and woven bag, in bundle or unbundle or in wooden cases.

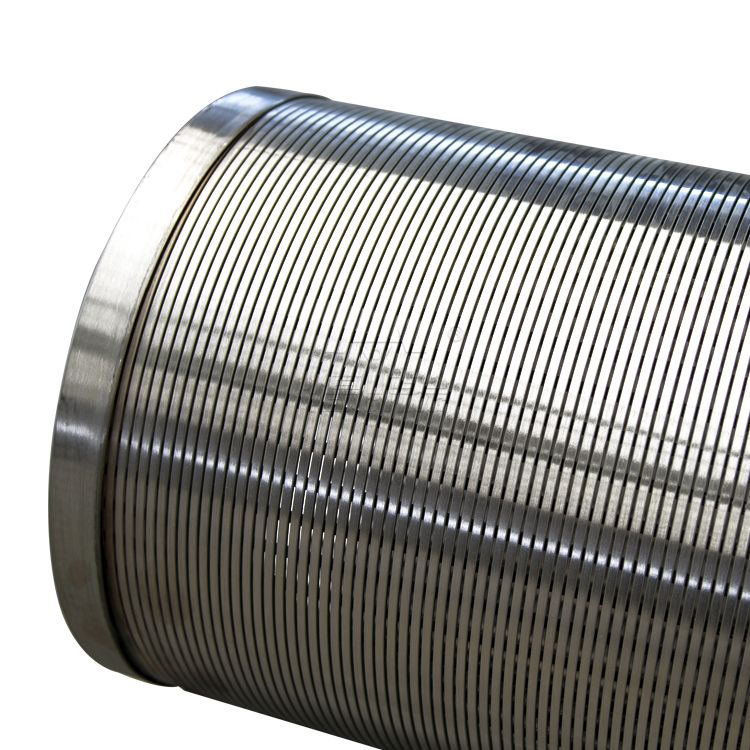

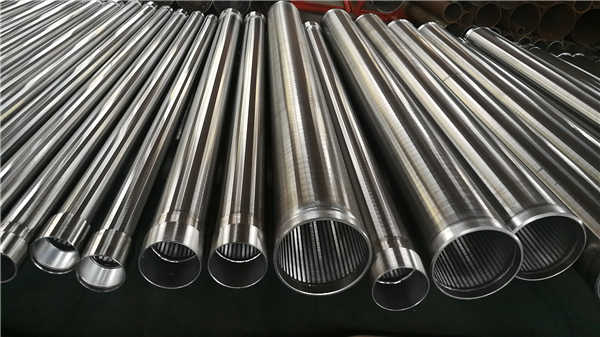

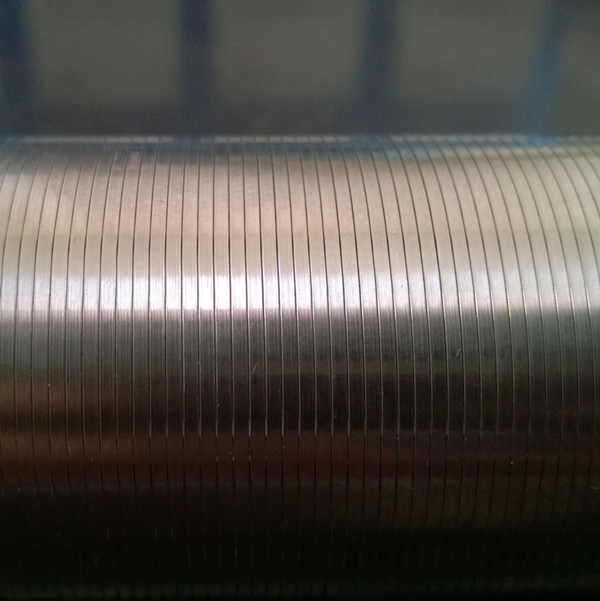

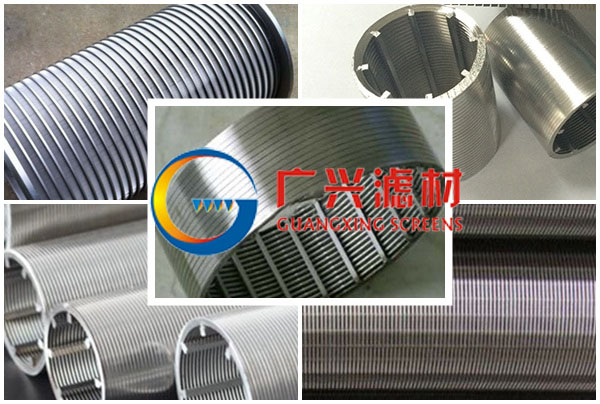

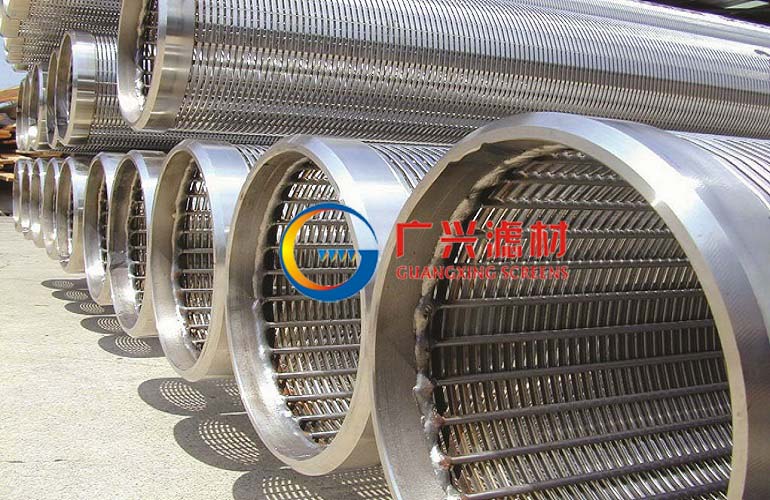

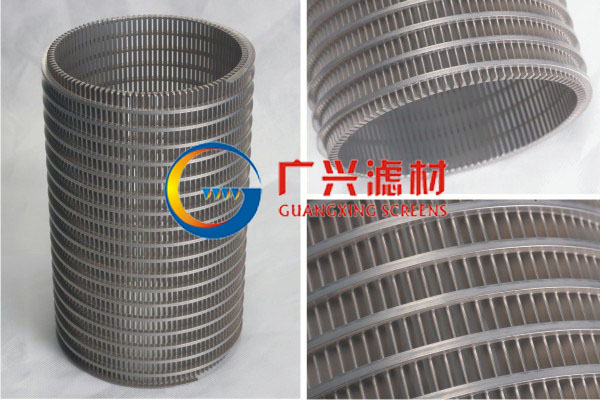

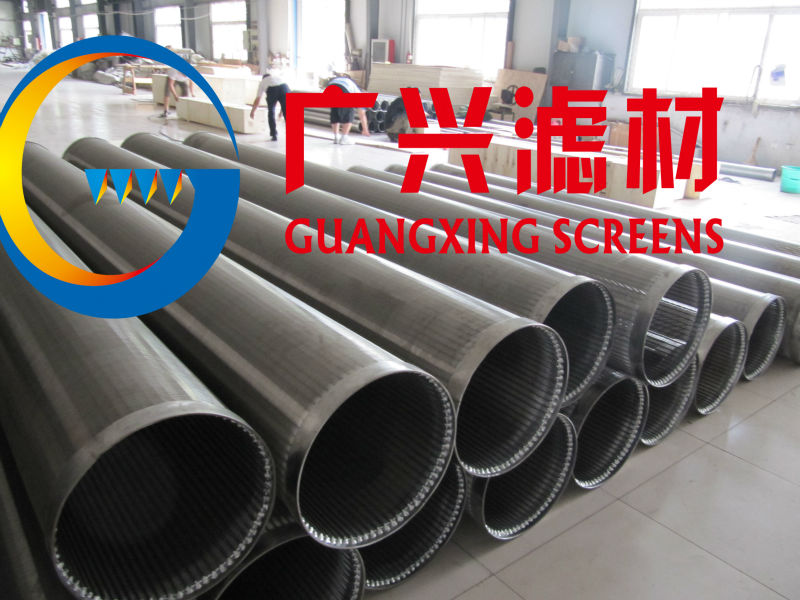

Product display:

Advantage:

MAXIMIZING FLOW RATES

When considering screens of equal length, diameter and slot size, flow rates through V-shaped well screens can be;

Three times higher than bridge-slot screens

Nine times higher than slotted casing

NON-CLOGGING SLOT

Continuous-slot well screens have V-shaped openings that narrowest at the outer face and widen inwardly, thus, over sized particles are retained outside the screen and particles passing through the narrow outside opening can enter the screen.

REDUCTIONS IN OPERATING COSTS

By using a Continous-slot well screen, savings can be achieved in pumping costs. Lower through-slot velocities mean that pressure drops are minimized, therefore;

Drawdowns are reduced.

Less energy is needed for pumping.

Flow rates are increased.

Less sand in the water reduces wear on the pumps.

Application:

The continuous-slot well screen is widely used throughout the world for water, oil, and gas wells, and is the dominant screen type used in the water well industry.

1.The continuous-slot well screen is recommended in the following situations;

2.Water wells where gravel packs will be installed

3.Thin aquifers, where maximum open area is required

4.Formation comprised of small or fine particles

5.Small diameter wells

Specification of Johnson Screen Stainless Stell Wedge Wire Filter Pipe

| Wedge Wire | Width(mm): 1.50 1.80 2.30 3.00 3.30 3.70 Height(mm): 2.20 2.50 2.70 3.60 4.30 4.70 5.60 6.30 7.00 |

| Support Rod | Width(mm): 2.30 3.00 3.30 3.70 Height(mm): 2.70 3.60 4.70 5.60 6.30 Round: From 2.50mm to 6.0mm |

| Note: other specifications available as per request | |

| Slot Size | 0.10, 0.15, 0.20, 0.25, 0.30… 6.00mm also achieved upon request. |

| Material | galvanized low carton (LCG), stainless steel (304,316 etc.) |

| Length | up to 6 meters. |

| Diameter | from 25mm to 1200mm. |

| End Connection | Plain beveled ends, flanged or threaded couplings |

OEM support, welcome your drawings / specifications

Stainless steel water well screen comprise of V-shape profile wire and the longitudinal help poles. Each meeting purpose of these wires is combination welded, so Water Well Screens has strong tightening and great mechanical property. The V-shape area plane can stay away from blockage and ensure the unrestricted water.

Pressing and Delivery:

Pressing Details: GUANGXING 304 316L water well screens/wedge wire screen/stainless steel wire networks with string association are gathered with bubble pack or woven sack and afterward with wooden strip or in wooden case(fumigation endorsement).

Conveyance time:GUANGXING 304 316L Johnson V write screen pipe/wedge wire screens/stainless steel wire networks with string association are conveyed with 3-30 days or rely upon amount.

WELL SCREEN PRICES:

Drilling

Wire Wrapped Water Well Screens

Manufacturer

Wire Screens