Introduction

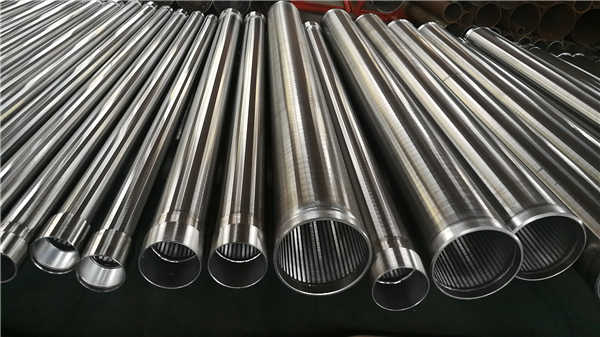

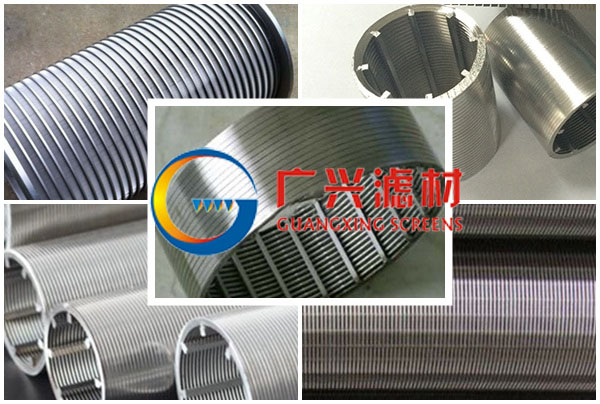

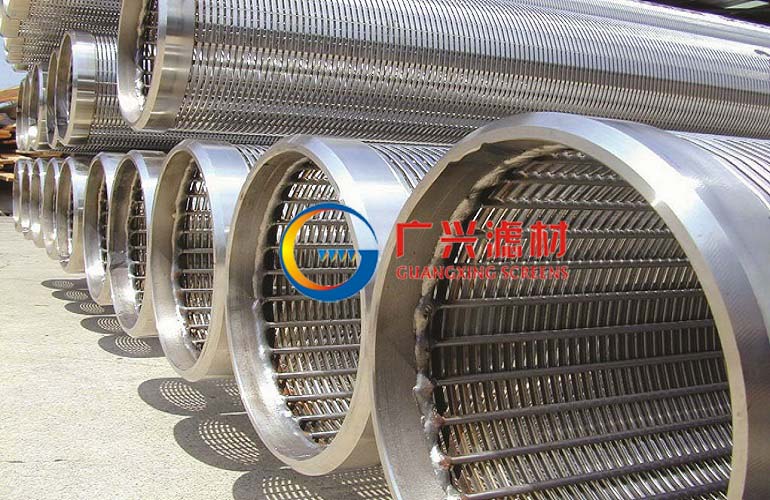

Water Well Screen is a highly versatile and efficient filtration solution used in various industries such as water, oil, and gas. It is made of high-quality materials like stainless steel, low carbon steel, and alloy steel. This article will delve into the features, technical parameters, applications, and customization options of the Water Well Screen, highlighting its importance in sand control, water well, oil well, mining, and irrigation.

Features of Water Well Screen

The Water Well Screen offers a range of features that make it an ideal choice for filtration purposes. Some of the key features include:

- Corrosion Resistance: The Water Well Screen is manufactured using materials like stainless steel, low carbon steel, and alloy steel, which provide excellent resistance against corrosion. This ensures its durability and longevity even in harsh environments.

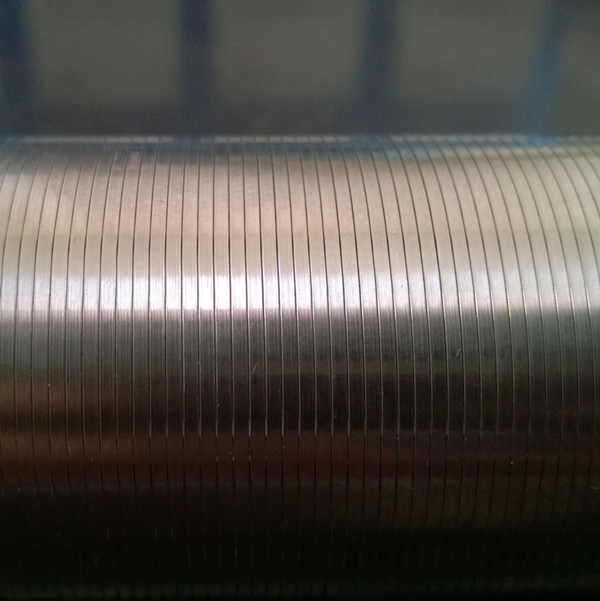

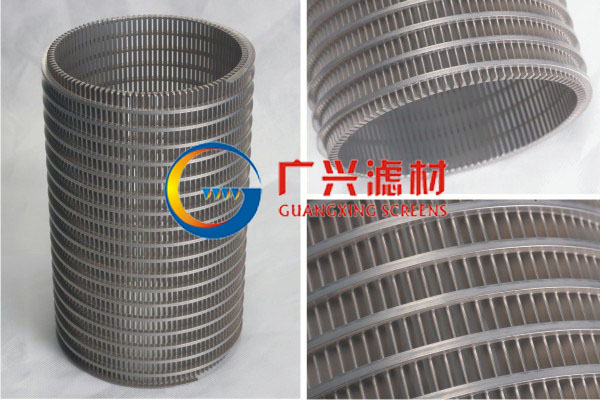

- Large Open Area: With its accurately designed slot sizes ranging from 0.025mm to 20mm, the Water Well Screen offers a large open area for efficient filtration. This allows for the smooth passage of water, oil, and gas while effectively filtering out impurities.

- High Strength: The Water Well Screen is built with precision and high strength, making it capable of withstanding high pressures and maintaining its structural integrity. This ensures its reliability and effectiveness in various applications.

- Precision Slot: The Water Well Screen is designed with precision slots, ensuring accurate filtration and sand control. The slot sizes can be adjusted according to specific requirements, allowing for customized filtration solutions.

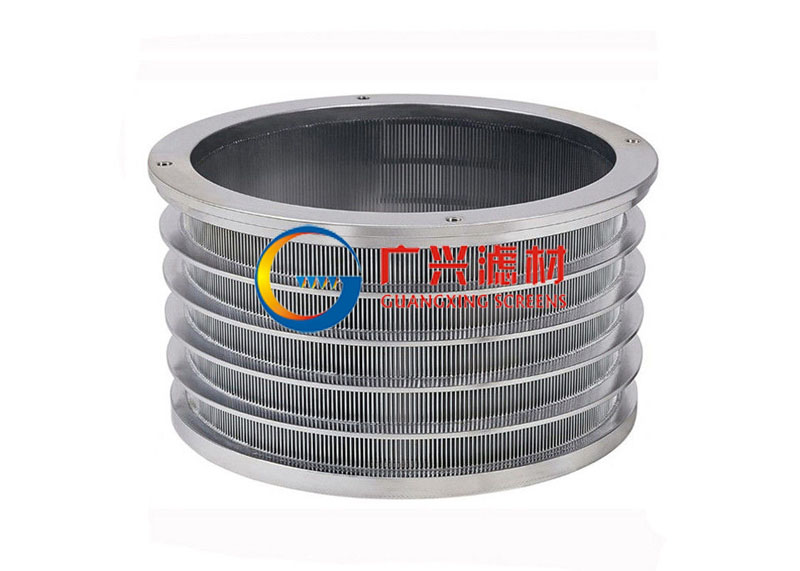

- Various Connection Types: The Water Well Screen offers versatility in terms of connection types. It is available with male/female thread, flange, and welded ring connections, providing flexibility for installation in different systems.

Technical Parameters of Water Well Screen

To better understand the technical aspects of the Water Well Screen, let’s take a look at its key parameters:

- Material: The Water Well Screen is available in stainless steel, low carbon steel, and alloy steel variants, offering options to suit specific industry requirements.

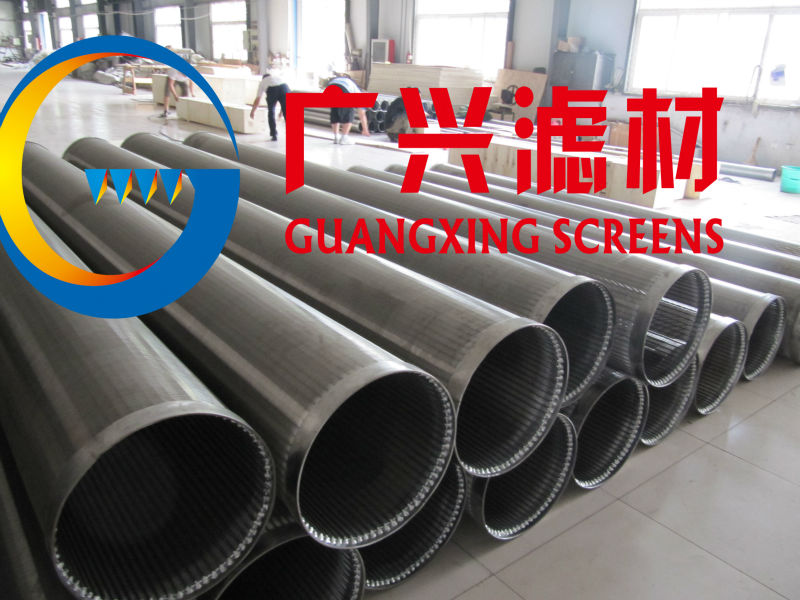

- Length: The standard length of the Water Well Screen ranges from 1m to 6m, ensuring compatibility with various well depths.

- Surface Treatment: The Water Well Screen can be treated with polishing, galvanizing, or painting, enhancing its corrosion resistance and aesthetic appeal.

- Certificate: The Water Well Screen is certified with ISO9001, API, and CE, ensuring its compliance with international quality standards.

- Connection Type: The Water Well Screen offers multiple connection types, including male/female thread, flange, and welded ring, providing ease of installation.

- Standard: The Water Well Screen complies with industry standards such as API, ASTM, ANSI, DIN, JIS, and BS, ensuring its compatibility with various systems.

- Filter Rating: The Water Well Screen offers a filter rating ranging from 25 to 3200 Micron, allowing for precise filtration based on specific application requirements.

- Application: The Water Well Screen is suitable for water, oil, and gas filtration, making it a versatile solution for various industries.

- Slot Size: The Water Well Screen provides slot sizes ranging from 0.025mm to 20mm, ensuring efficient filtration and sand control.

- Pressure Rating: The Water Well Screen can withstand pressure ratings ranging from 150 to 2500 PSI, making it suitable for high-pressure applications.

Applications of Water Well Screen

The Water Well Screen, with its exceptional features and technical parameters, finds extensive applications in various industries. Some of the key applications include:

- Water Filtration: The Water Well Screen is widely used for water filtration purposes, ensuring the removal of impurities and providing clean water for domestic, agricultural, and industrial use.

- Oil Filtration: In the oil industry, the Water Well Screen plays a crucial role in oil filtration, preventing the entry of sand and other particles into the oil well. This helps in maintaining the quality and purity of the extracted oil.

- Gas Filtration: The Water Well Screen is also utilized for gas filtration, ensuring the removal of impurities and contaminants from natural gas sources. This enhances the efficiency and safety of gas processing operations.

- Sand Control: One of the primary applications of the Water Well Screen is sand control. It effectively filters out sand particles, preventing their entry into the well and minimizing the risk of equipment damage and production decline.

- Mining and Irrigation: The Water Well Screen is widely used in mining and irrigation applications. It helps in filtering out unwanted particles and sediments, ensuring the efficient flow of water and preventing clogging of irrigation systems.

Customization Options for Water Well Screen

Guangxing Water Well Screen offers customization options to meet specific requirements. Some of the key customizationoptions include:

- Material: The Water Well Screen can be customized to be made from stainless steel, low carbon steel, or alloy steel, depending on the specific needs of the application.

- Slot Size: The slot size of the Water Well Screen can be adjusted according to the desired filtration requirements. It can range from 0.025mm to 20mm, allowing for precise filtration based on the application.

- Size: The Water Well Screen is available in various sizes, including 3″, 4″, 6″, 8″, 10″, 12″, and 14″. This ensures compatibility with different well diameters and depths.

- Surface Treatment: Guangxing Water Well Screen offers surface treatment options such as polishing, galvanizing, and painting. This not only enhances the corrosion resistance but also provides an aesthetic appeal.

- Packaging and Delivery: The Water Well Screen is packaged in wooden boxes or containers to ensure safe transportation. Guangxing guarantees a delivery time of 5-8 work days, ensuring prompt availability of the product.

Frequently Asked Questions (FAQ)

- What are the main materials used in Water Well Screen production?

The Water Well Screen is primarily made from stainless steel, low carbon steel, and alloy steel. These materials offer excellent corrosion resistance and durability.

- What are the connection types available for Water Well Screen installation?

The Water Well Screen offers various connection types, including male/female thread, flange, and welded ring. This provides flexibility for installation in different systems.

- What is the range of slot sizes available in Water Well Screen?

The Water Well Screen provides slot sizes ranging from 0.025mm to 20mm. This allows for precise filtration based on specific application requirements.

- What certifications does Guangxing Water Well Screen hold?

Guangxing Water Well Screen is certified with ISO9001, API, and CE, ensuring its compliance with international quality standards.

- What are the main applications of Water Well Screen?

The Water Well Screen finds applications in water, oil, and gas filtration, sand control, mining, and irrigation. It is a versatile solution for various industries.

Conclusion

The Water Well Screen is a highly efficient and versatile filtration solution used in water, oil, and gas industries. With its excellent corrosion resistance, large open area, accurate slot sizes, high strength, and precision, it provides the best solution for well water filtration. The Water Well Screen, available in various sizes and connection types, can be customized to meet specific requirements. Its applications range from water and oil filtration to sand control, mining, and irrigation. With Guangxing commitment to quality and prompt delivery, the Water Well Screen proves to be the ultimate choice for efficient and reliable filtration in diverse industries.