Stainless Steel Filter Nozzle

The stainless steel filter nozzle is a cutting-edge water treatment component, designed to replace traditional plastic filter nozzles with a more durable and efficient solution. This document provides an in-depth look at the composition, materials, types, characteristics, uses, features, and advantages of stainless steel filter nozzles.

Composition

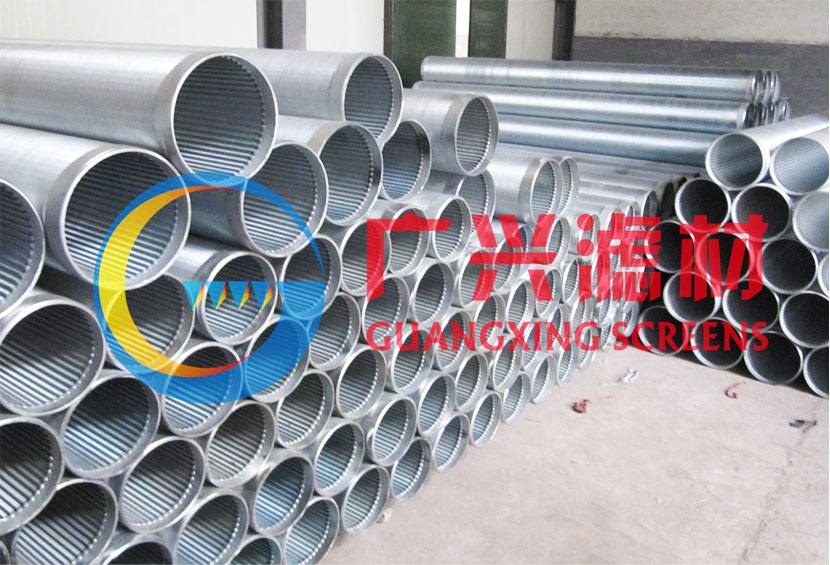

The stainless steel filter nozzle is composed of wedge wires that are welded to support rods. This construction provides a robust, reliable, and high-performing filtration solution.

Materials

Stainless steel filter nozzles are manufactured from high-quality stainless steel and alloys, tailored to specific applications. Common materials include:

- 304 Stainless Steel

- 304L Stainless Steel

- 316 Stainless Steel

- 316L Stainless Steel

- Other Alloys: Depending on the application and required properties.

Types of Wedge Wire Nozzles

There are two primary types of wedge wire nozzles:

- Single Wedge Wire Nozzle

- Double Wedge Wire Nozzle

Characteristics

Stainless steel filter nozzles exhibit several key characteristics:

- Corrosion Resistance: Ideal for use in harsh and corrosive environments.

- Durability: Long-lasting performance under high pressures and temperatures.

- Precision: Accurate slot dimensions ensure effective filtration.

- High Strength: Resilient against mechanical stress.

- Heat Resistance: Suitable for high-temperature applications.

Product Specifications

From the appearance, there are mainly four types of metal wedge wire nozzles, single-head wedge wire filter nozzles, double-head wedge wire filter nozzles, single-flow rated and dual-flow rated filter nozzles, and long-handled filter nozzles.

Uses

Stainless steel filter nozzles are versatile and used in various applications, including:

- Water Treatment Plants

- Desalination Plants

- Chemical Processing

- Petroleum Industry

- Food and Beverage Industry

- Pharmaceutical Industry

Features of Products

Stainless steel filter nozzles offer several notable features:

- High Open Area:

- Enhances flow rates and filtration efficiency.

- Reduces pressure drop across the filter.

- V-Shaped Profile Wire:

- Prevents clogging.

- Ensures continuous and uninterrupted flow.

- Robust Construction:

- Made from high-quality stainless steel for durability and strength.

- Withstands high-pressure and high-temperature conditions.

- Easy Installation and Maintenance:

- Designed for ease of installation in various filtration systems.

- Simple to clean and maintain, ensuring long-term performance.

Advantages

Stainless steel filter nozzles provide numerous advantages:

- Enhanced Filtration Efficiency:

- High open area design ensures maximum fluid throughput and efficient filtration.

- Long Service Life:

- Durable stainless steel construction offers a long lifespan, reducing the need for frequent replacements.

- Corrosion and Heat Resistance:

- Suitable for use in corrosive environments and high-temperature applications, ensuring reliable performance.

- Low Maintenance:

- Easy to clean and maintain, reducing downtime and operational costs.

- Versatility:

- Applicable in various industries, including water treatment, chemical processing, and food and beverage production.

Conclusion

Stainless steel filter nozzles represent a significant advancement in water treatment technology, offering superior performance, durability, and efficiency compared to traditional plastic filter nozzles. Constructed from high-grade materials such as 304 and 316 stainless steel, these nozzles are designed to meet the rigorous demands of various industrial applications. Their innovative design, featuring wedge wires welded to support rods, ensures optimal filtration and flow characteristics, making them an essential component for modern filtration systems. With their robust construction, ease of maintenance, and long service life, stainless steel filter nozzles provide a reliable and cost-effective solution for maintaining efficient and effective filtration systems.