stainless steel well screens and well casings Introduction

Stainless steel screens and casings play a

crucial role in various industries, such as water well drilling, oil and gas

extraction, and environmental monitoring. They are essential for filtering out

particles, sand, and debris, ensuring the efficient operation of equipment and

the quality of the extracted resources. This comprehensive guide will provide an

in-depth understanding of how stainless steel screens and casings work, their

applications, manufacturing processes, material selection, and maintenance.

Stainless steel: A versatile material

Stainless steel is a corrosion-resistant

alloy of iron, chromium, nickel, and other elements. Its corrosion resistance, mechanical

strength, and low

maintenance requirements make it an ideal material for screens and casings

in challenging environments. Stainless steel is available in various grades,

each with different properties, making it suitable for specific applications.

Stainless steel grades

There are several stainless steel grades

used for screens and casings, including:

- 304/304L: General-purpose stainless

steel with good corrosion resistance and mechanical properties. - 316/316L: A more corrosion-resistant

grade, suitable for applications in harsh environments or with aggressive

fluids.

Duplex stainless steels: These grades have a dual-phase microstructure

of austenite and ferrite, offering higher strength and corrosion resistance

than conventional stainless steels.

Material selection depends on factors such

as the chemical composition of the fluid, temperature, pressure, and required

strength.

The role of screens and casings in well

construction

Screens and casings are essential

components in the construction of water wells, oil and gas wells, and environmental

monitoring wells. Screens are typically installed in the production zone of

the well, allowing fluids to flow into the wellbore while filtering out sand and

other particles. Casings, on the other hand, are large-diameter pipes that are

inserted into the well to provide structural support and isolate different

geological formations.

Screens

Screens are installed in well completions

to:

- Filter out sand, silt, and other

particles - Protect the wellbore from collapse

- Minimize turbulence and flow

restrictions - Prevent damage to pumps and other

equipment - Ensure the efficient production of

water, oil, or gas

There are various types of screens

available, such as wire-wrapped screens, pre-packed screens, and slotted liners.

The choice of screen depends on factors such as the size of the particles to be

filtered, the well’s production rate, and the formation’s characteristics.

Casings

Casings play a crucial role in well

construction by:

- Providing structural support for the

wellbore - Isolating different geological

formations to prevent cross-contamination - Protecting the well from external

contaminants and pressure

changes - Facilitating the installation of

production equipment

Well casings can be made from various

materials, including carbon steel, stainless steel, and plastic. Stainless steel

casings are preferred in corrosive environments or when the well is exposed to

aggressive fluids.

Manufacturing processes for stainless

steel screens and casings

The manufacturing process for stainless

steel screens and casings primarily involves cutting, forming, and welding

operations. Some common manufacturing processes include:

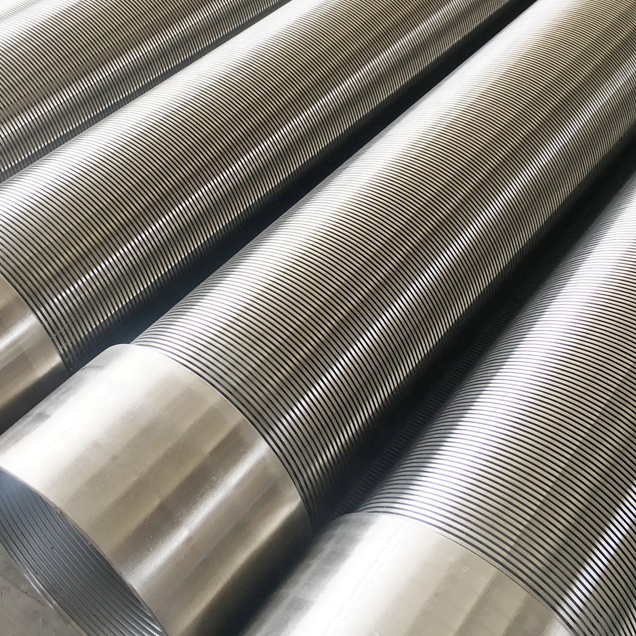

Wire-wrapped screens

Wire-wrapped screens are manufactured by

winding a continuous wire around a series of support

rods, forming a V-shaped slot. The wire is typically welded to the support

rods, creating a strong and rigid structure. The slot size can be easily

controlled by adjusting the wire spacing and shape.

Pre-packed screens

Pre-packed screens consist of a

wire-wrapped or slotted screen surrounded by a layer of sand or gravel, known as

the filter

pack. The filter pack is held in place by an outer shroud, which is

typically made of perforated stainless steel. Pre-packed screens offer improved sand

control and reduced installation time compared to conventional screens.

Slotted liners

Slotted liners are made by cutting a

series of slots into a stainless steel pipe. The slot size and pattern can be

customized to meet specific project requirements. Slotted

liners are less expensive than wire-wrapped screens but offer lower

filtration efficiency and can be more prone to plugging.

Well casings

Well casings are typically manufactured

from seamless or welded stainless steel pipes. The pipes are cut to the required

length and threaded or coupled to create a continuous casing string. In some

cases, the casing may be coated with corrosion-resistant materials or fitted

with centralizers to improve its performance.

Installation and maintenance

Proper installation and maintenance of

stainless steel screens and casings are essential to ensure the efficient

operation of the well and minimize the risk of failure.

Installation

During the installation process, it’s

crucial to:

- Select the appropriate screen and

casing materials based on the well’s conditions - Properly size and position the

screens to ensure efficient filtration and production - Install centralizers and other

accessories as needed to maintain the casing’s position and integrity - Ensure proper handling and storage of

the materials to prevent damage and corrosion

Maintenance

Regular maintenance is essential to

prolong the life of stainless steel screens and casings. Maintenance activities

may include:

- Periodic inspectionsand monitoring to

identify signs of corrosion, damage, or wear - Cleaning and flushing the screens to

remove accumulated debris and prevent plugging - Monitoring well performance and

adjusting production rates to minimize sand production and prevent erosion - Implementing corrosion

control measures, such as cathodic protection or chemical treatments

| BASE PIPE | SLIP ON SCREEN JACKET | |||||||||

| Nominal Diameter |

Pipe OD (mm) |

Weight lb/ft W.T[mm] |

Hole size In |

Holes per foot | Total Area of holes in2/ft |

Screen OD (in) |

Open area of screen in2/ft SLOT |

|||

| 0.008” | 0.012” | 0.015” | 0.020” | |||||||

| 2-3/8 | 60 | 4.6[4.83] | 3/8 | 96 | 10.60 | 2.86 | 12.68 | 17.96 | 21.56 | 26.95 |

| 2-7/8 | 73 | 6.4[5.51] | 3/8 | 108 | 11.93 | 3.38 | 14.99 | 21.23 | 25.48 | 31.85 |

| 3-1/2 | 88.9 | 9.2[6.45] | 1/2 | 108 | 21.21 | 4.06 | 18.00 | 25.50 | 30.61 | 38.26 |

| 4 | 101.6 | 9.5[5.74] | 1/2 | 120 | 23.56 | 4.55 | 20.18 | 28.58 | 34.30 | 42.88 |

| 4-1/2 | 114.3 | 11.6[6.35] | 1/2 | 144 | 28.27 | 5.08 | 15.63 | 22.53 | 27.35 | 34.82 |

| 5 | 127 | 13[6.43] | 1/2 | 156 | 30.63 | 5.62 | 17.29 | 24.92 | 30.26 | 38.52 |

| 5-1/2 | 139.7 | 15.5[6.99] | 1/2 | 168 | 32.99 | 6.08 | 18.71 | 26.96 | 32.74 | 41.67 |

| 6-5/8 | 168.3 | 24[8.94] | 1/2 | 180 | 35.34 | 7.12 | 21.91 | 31.57 | 38.34 | 48.80 |

| 7 | 177.8 | 23[8.05] | 5/8 | 136 | 42.16 | 7.58 | 23.32 | 33.61 | 40.82 | 51.95 |

| 7-5/8 | 194 | 26.4[8.33] | 5/8 | 148 | 45.88 | 8.20 | 25.23 | 36.36 | 44.16 | 56.20 |

| 8-5/8 | 219 | 32[8.94] | 5/8 | 168 | 51.08 | 9.24 | 28.43 | 40.98 | 49.76 | 63.33 |

| 9-5/8 | 244.5 | 36[8.94] | 5/8 | 188 | 58.28 | 10.18 | 31.32 | 45.15 | 54.82 | 69.77 |

| 10-3/4 | 273 | 45.5[10.16] | 5/8 | 209 | 64.79 | 11.36 | 34.95 | 50.38 | 61.18 | 77.86 |

| 13-3/8 | 339.7 | 54.5[9.65] | 5/8 | 260 | 80.60 | 14.04 | 37.80 | 54.93 | 66.87 | 85.17 |

Applications of stainless steel screens

and casings

Stainless steel screens and casings are

used in various industries, some of which include:

Water well drilling

In water well drilling, stainless steel

screens and casings are used to filter out sand and silt, ensuring clean and

safe drinking water. They also provide structural support to the wellbore,

preventing collapse and contamination.

Oil and gas extraction

In the oil and gas industry, stainless

steel screens and casings are vital for efficient production and maintaining

well integrity. They are used to filter out sand and other particles that can

damage the wellbore, as well as isolate different geological formations to

prevent cross-contamination.

Environmental monitoring

Stainless steel screens and casings are

also used in environmental monitoring wells to collect samples of groundwater or

soil gas. The corrosion resistance and low maintenance

requirements of stainless steel make it an ideal material for these

applications, where long-term performance is critical.

Geothermal energy

In geothermal

energy production, stainless steel screens and casings are used to withstand

high temperatures and corrosive fluids. They ensure efficient heat extraction

and prevent damage to the wellbore and equipment.

Advantages of stainless steel screens and

casings

Some benefits of using stainless steel

screens and casings in well construction include:

- Corrosion resistance: Stainless

steel’s corrosion-resistant properties make it suitable for use in

challenging environments, such as high temperatures, aggressive fluids, or

corrosive soils. - Mechanical strength: Stainless steel

offers high mechanical strength, improving the well’s structural integrity

and resistance to external forces. - Low maintenance: The corrosion

resistance and durability of stainless steel reduce maintenance

requirements, resulting in lower long-term costs. - Customization: Stainless steel

screens and casings can be manufactured in various grades, sizes, and

configurations, allowing for customization to

meet specific project requirements.

Conclusion

Stainless steel screens and casings play a

vital role in ensuring the efficient operation and longevity of wells in various

industries. Their corrosion resistance, mechanical strength, and low maintenance

requirements make them an ideal material

choice for challenging environments. By understanding how stainless steel

screens and casings work, the manufacturing processes involved, and their

applications, it is possible to make informed decisions about the most suitable

materials and designs for specific well construction projects. Proper

installation and maintenance practices will further ensure the best possible

performance and longevity of these essential well components.