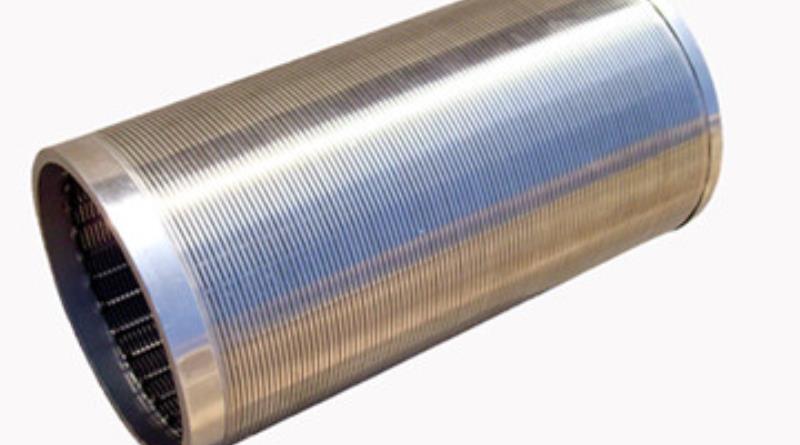

Perforated Pipe for Wedge Wire adopted advanced ways to soak. Our water drainage pipes are always fully accessible for inspection and maintenance.

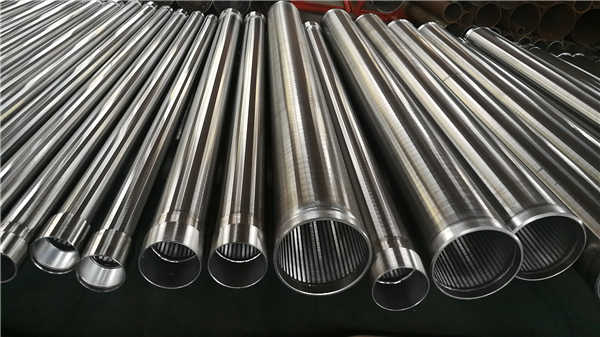

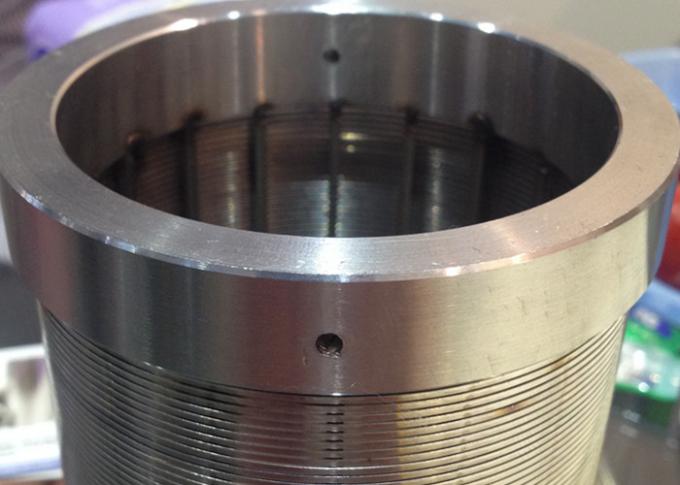

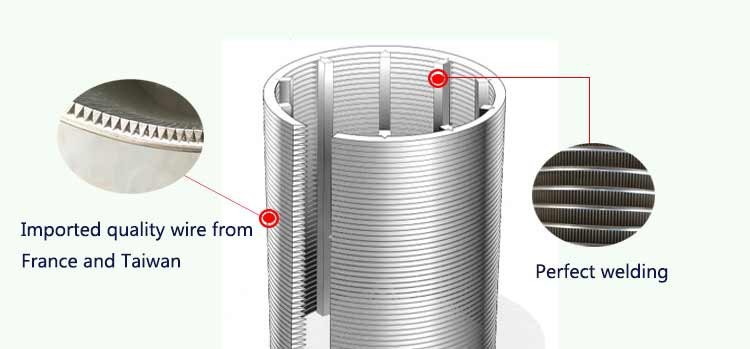

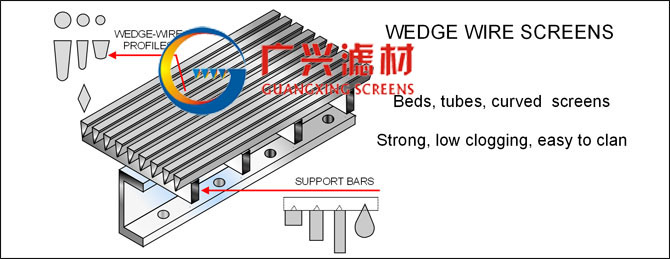

Wedge wire screens are manufactured by resistance welding V-shaped wire on support rods. Our wedge wire screen begins with the highest quality raw wire then is made into screen that is cut, shaped, fabricated and cleaned.

Manufacturing perforated pipe in diameters from 0.3m to 3.6m to fit any situation, we can produce pipe systems or vertical rings or a combination of the two. We can also provide a full design and detailing service, consistent with SUDS, using the latest software.

Perforated Pipe for Wedge Wire is designed to control various processing conditions including volumetric flow rate, minimum dimensional media retention, minimum open area and fluid pressure capabilities. Federal Screen is able to professionally work a large variety of stainless steels and alloys into both standard or customizable screen applications and accessory products.

Materials

Perforated casing pipe is available in two different series of wire materials:

Carbon/plain steel: low carbon steel, mild carbon steel, high carbon steel

Stainless steel: 201,202, 304, 316, 321, 410, 430

Other available, please ask

We can determine the suitability and performance of a soak away or infiltration system according to three criteria:

The capacity of the soil to infiltrate water – the “infiltration coefficient”

Existing or historic groundwater levels – should be at least 1m below the invert of the intended soak away

The plan area available for sitting the soak away unit

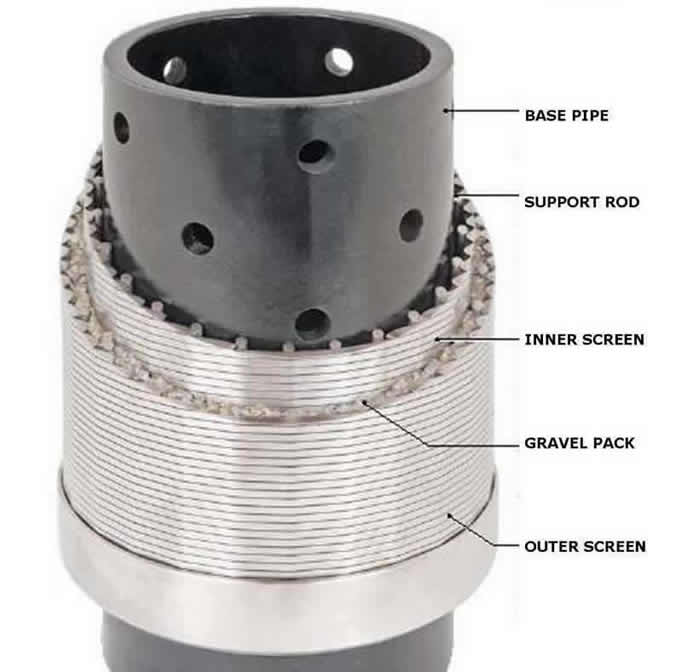

Wedge Wire Water Screen Pipe can be made single layer or double layers. The single layer can be cut to many kinds of sieve plate. The sieve plate mainly used for water treatment and paper making industry.

| Screen Size | Inside Diameter | Outside Diameter | OD of Female Threaded End | |||

| mm | in | mm | in | mm | in | mm |

| 51 | 2 | 51 | 2 5/8 | 67 | 23/4 | 70 |

| 76 | 3 | 76 | 3 5/8 | 92 | 33/4 | 95 |

| 102 | 4 | 102 | 4 5/8 | 117 | 43/4 | 121 |

| 127 | 5 | 127 | 5 5/8 | 143 | 53/4 | 146 |

| 152 | 6 | 152 | 6 5/8 | 168 | 7 | 178 |

| 203 | 8 | 203 | 8 5/8 | 219 | 91/4 | 235 |

| 254 | 10 | 254 | 10 3/4 | 273 | 113/8 | 289 |

| 305 | 12 | 305 | 12 3/4 | 324 | 133/8 | 340 |

| 356 | 131/8 | 333 | 14 | 356 | – | – |

| 406 | 15 | 381 | 16 | 406 | – | – |

| 508 | 18 3/4 | 476 | 20 | 508 | – | – |

Applications:

Cased- and open hole environments.

Suitable for gravel-pack and standalone operations.

Sand free production in vertical or horizontal wells.