Materials of deep sand water well filter pipe

deep well pre-packed filter pipe, sand control pre-packed wedge wire pipe

Pre-packed screens can be fabricated in stainless steel 304, 316L, Low carbon steel or other special alloys like Monel 400. Materials are available for specific alloy as required.

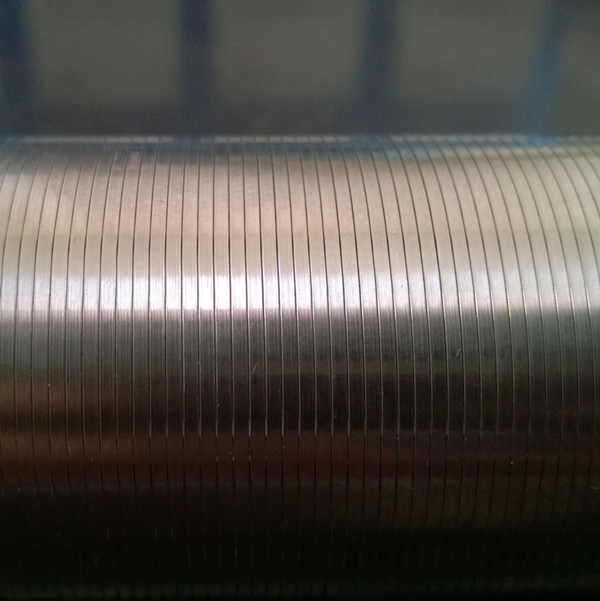

Gravel pre-packed wedge wire screen (Johnson type screens) are manufactured by a or v wedge shaped wire around an internal array of longitudinal support rods. The world advanced all-weld technology is used with the beach interesting point of these wire fusion welded, which creates the robust construction and excellent mechanical performance.Vor wedge shaped profile wire wraps around the support rods over the full length of the wedge wire screen creating a continuous slot opening, hence the screen allows water(oil) to enter your well freely in ample quantities, while at the same time keeps the majority of sand and gravel out of the well. The slots can be changed according to different strata.

Water well screen pipe is made up of Vee-shaped wire and round rod in each intersection welded together.

Each slot opening between adjacent wires is V-shaped, resulting from the special shape of the wire used to form the screen surface.

The V-shaped openings, designed to be non-clogging, are narrowest at the outer face and widen inwardly.It has the firm structure, high temperature resistant, corrosion resistance, good mechanical performance, long service life, safe and reliable, etc.

It also can be used for a variety of medium.

Technical data for reference , we can produce as your requirements

| Size(inch) | O.D(mm) | Slot(inch) | CollapseStrength

(Psi) |

Tensile Weight(Ton) | Wrap(thick*deep)(mm) | Rods(mm) |

| 4 | 117 | 0.040 | 395 | 6 | 2.2*3.0 | 3.8mm/22 |

| 4 | 114.3 | 0.040 | 395 | 6 | 2.3*3.0 | 3.8 mm /22 |

| 6 | 168.3 | 0.040 | 252 | 8 | 2.3*3.5 | 3.8 mm /32 |

| 8 | 219.1 | 0.010 | 399 |

10.5 |

3.0*5.0 | 3.8 mm /48 |

| 8 | 219.1 | 0.020 | 370 | 10.5 | 3.0*5.0 | 3.8 mm /48 |

| 8 | 219.1 | 0.040 | 323 | 10.5 | 3.0*5.0 | 3.8 mm /48 |

| 10 | 273.1 | 0.010 | 206 | 11 | 3.0*5.0 | 3.8 mm /50 |

| 10 | 273.1 | 0.020 | 191 | 11 | 3.0*5.0 | 3.8 mm /50 |

| 10 | 273.1 | 0.040 | 167 | 11 | 3.0*5.0 | 3.8 mm /50 |

Advantage:

1.A continuous slot opening which significantly increases the available open area, thus providing greater access to the water bearing zone

2.A V-shaped profile wire which avoids clogging and ensures an uninterrupted flow.

3.A uniform and efficient well development due to the continuous slot opening.

4.Ladder-like wire welded screens have a strong structure and high open area, as well as accurate slot dimension.

5.Ladder-like wire welded screens have the features of easy backwashing, last long, safety and reliability as well as low comprehensive cost.

The Double-layer pre-filled wedge screen consists of a base tube with API standard, a double layer high precision wedge-shaped wire filter and a middle filler filter material.

Product Features: 1, high-precision screen slot can effectively play the role of sand control and protection of the medium.

2, the use of pre-filled wedge-shaped screen can reduce drilling hole diameter, save drilling time, reduce drilling costs.

3, the use of pre-filled wedge screen can reduce the workload of construction personnel, improve the success rate of drilling.

4, filter material can be used to effectively inhibit the microbial ceramic particles, or standard sand and resin particles.

5, through adjusting the screen slot can effectively prevent the filter material leakage, prolong the service life.

6, in the long run, pre-filled wedge screen screen for customers to bring lower cost of use.

7, can be used according to the requirements of the built-in API standard base tube to increase the overall pressure of the screen, for deeper strata.

Features & Benefits

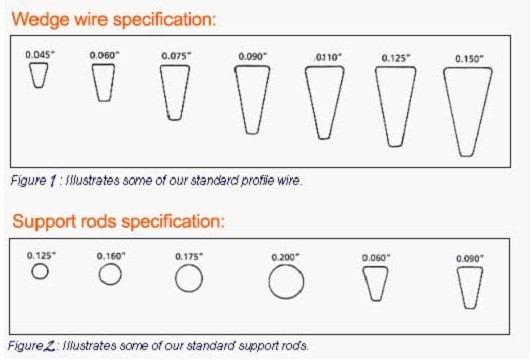

1. Keystone design for self cleaning and maximum flow optimizing productivity

2. Various wire shapes and slot sizes for specific requirement

3. Corrosion and erosion resistant

4. Easy and fast installation minimizing product lead times

5. Virtually maintenance-free

Applications

1. Heavy oil, sand oil, light oil, SAGD, CBM, bitumen, thermal

2. Water injection, bi-modal sand, carbonates, thin pay

3. Horizontal, vertical , deviated oil and gas and water wells