Wire Wrapped Screen

How to calculate the strength of a Wire Wrapped Screen filter on pressure

pressure = Force area (f=ps), pressure = stress/Compression area (P=F/S). The

physical pressure is the force that occurs on the contact surface of two

objects, or the vertical force of a gas on a solid or liquid surface, or the

vertical force of a liquid on a solid surface.

Traditionally, in mechanics and most engineering disciplines, the term “stress”

is synonymous with pressure in physics. The pressure on the surface of a solid

is usually the result of elastic deformation, which generally belongs to the

contact force.

479

Pressure on the surface of liquids and gases is usually the result of

gravitational and molecular motions. The direction of the pressure is usually

perpendicular to the contact surface of the object.

| Pipe base screen | ||||

| Screen |

API Pipe |

|||

| ID(mm) | OD(mm) | SLOT(mm) | Normal size(inch) | OD(mm) |

| 63 | 73 | 0.10-3 | 2-3/8” | 60.3 |

| 74 | 85 | 0.10-3 | 2-7/8” | 73 |

| 92 | 102 | 0.10-3 | 3-1/2” | 88.9 |

| 103 | 127 | 0.10-3 | 4” | 101.6 |

| 116 | 130 | 0.10-3 | 4-1/2” | 114.3 |

| 129 | 142 | 0.10-3 | 5” | 127 |

| 142 | 154 | 0.10-3 | 5-1/2” | 139.7 |

| 172 | 184 | 0.15-3 | 6-5/8” | 168.3 |

| 183 | 195 | 0.15-3 | 7” | 177.8 |

| 220 | 232 | 0.15-3 | 8-5/8” | 219.1 |

| 246 | 260 | 0.25-3 | 9-5/8” | 244.48 |

| 276 | 290 | 0.25-3 | 10-3/4” | 273.05 |

| 342 | 355 | 0.25-3 | 13-3/8” | 339.70 |

| Length of screen 5m*1 | Length of pipe( m) | 5.8 | ||

| Length of screen 4.5 m * 2 | 9.3~9.6 | |||

| Length of screen 5 m * 2 | 11~12 | |||

If the observed pressure is not perpendicular to the contact surface, it is

usually the result of the interaction of pressure and friction.

Wire Wrapped Screen filter pipe Material: 201, 205, 304, 304L, 316, 316L, 321,

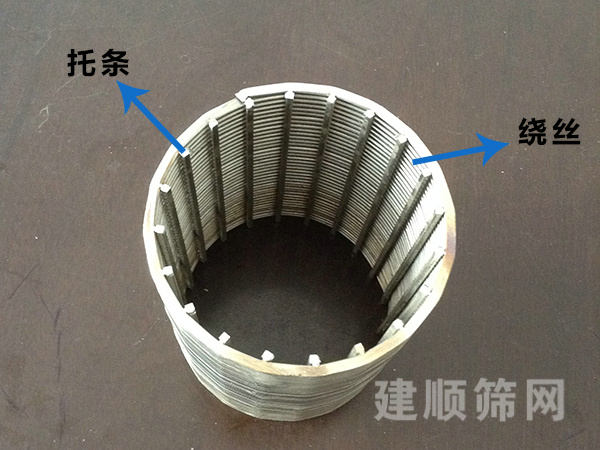

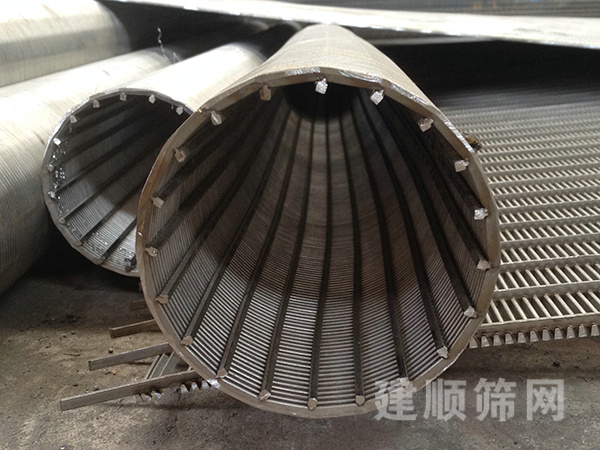

such as stainless steel wire. Features: Wire Wrapped Screen filter is also a

kind of screen. The winding screen is composed of “V” type stainless steel wire

and stainless steel support bar, which is connected together by welding and

supporting strip, and the strict continuity and integrity make the full welded

wire-mesh liner have the same gap and bear small performance.

Compared with other existing filtration elements, it has the characteristics of

strong structure, high tensile strength, strong compressive strength, corrosion

resistance, high temperature resistance, easy to jam and easily flush.

Product specifications and raw materials can be customized according to customer

needs, all products are strictly in accordance with national standards for

production testing to ensure product quality, so as to ensure the interests of

the vast number of customers to the most economic input to obtain the highest

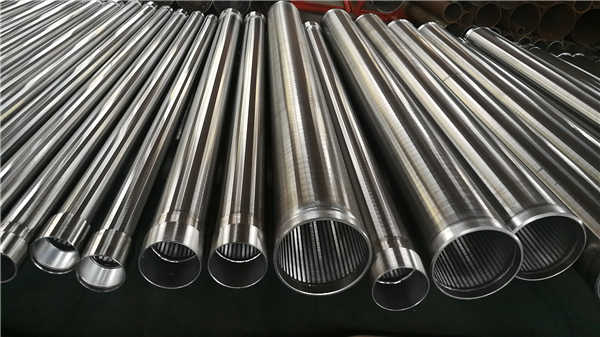

production efficiency. Usage: The Wire Wrapped Screen filter is a kind of

water-filtering equipment with perforations.

Can be with deep pump, submersible pump supporting the use, can also be used for

water treatment equipment, environmental protection, seawater conversion for

industrial water and water desalination treatment, water treatment, softening

treatment, petrochemical industry, petroleum products, terminal filtration and

chemical acid, alkali liquid filtration, alcohol and other organic solution

recovery filtration.

well screen/water well screen filter/sand control oilwell screen

1.

GENERAL REQUIREMENTS

:

The quality of stainless steel should be such that its life once installed will not be less than 20 years.

1.1

The screen shall be able to withstand without deterioration normal handling from the place of manufacture to the place of erection and of being stored in the open yard in any weather to which these may be exposed.

The components separately and together shall neither progressively corrode nor suffer deterious change of property in the presence of the materials and bacteria which may encountered below the formation surface at the place of erection or by exposure to weather of by immersion.

The stainless steel screen shall be so manufactured that these will not suffer significant damage due to impact or abrasion such as may occur when a sand bailer is used for well maintenance.

2.

MATERIALS

:

AISI Type-304

3.

CONSTRUCTION

:

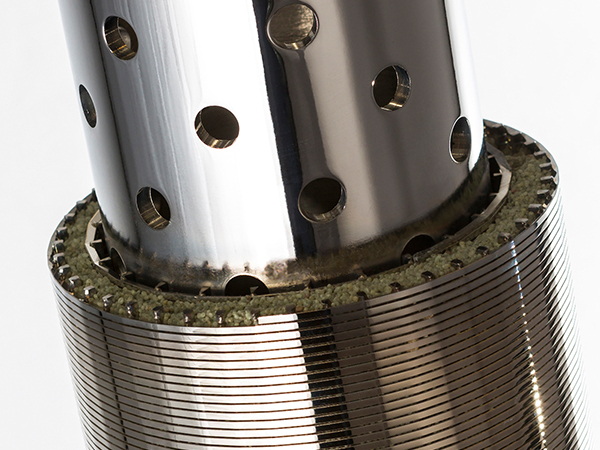

The screen shall be manufactured in the all welded continuous slot wedge wire or support rod construction, with the latest electronically controlled welding system, ensuring greater fusion strength between the profile wedge wire and support rods maintaining accurate slot opening. The shape of the wedge wire shall be such that when welded to support rods, it will increase the slot openings inwards. The wedge wire shall firmly be attached to the supporting rods which will, in turn, be attached to the coupling adapter. The bidders shall give details of the size and shape of wires and the number of support rods with size and shape.

4.

JOINTS

:

Each end of the screen shall be threaded as per BS-21-1973 (11TPI). Each screen length shall be provided with a coupler to the same standard.

5.

CIRCULARITY AND STRAIGHTNESS

:

The bores of the screen and joints separately and when jointed shall be rounded, smooth and straight.

6.

STRENGTH OF COMPONENTS

:

The components separately and jointed together shall be able to withstand without deterioration the following conditions :-