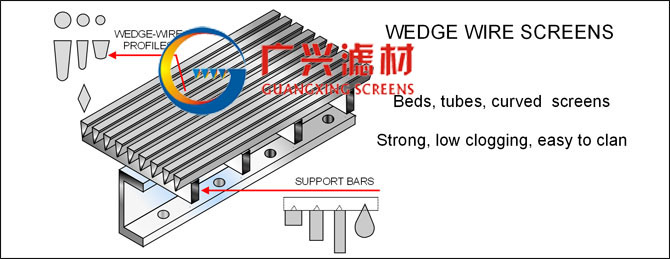

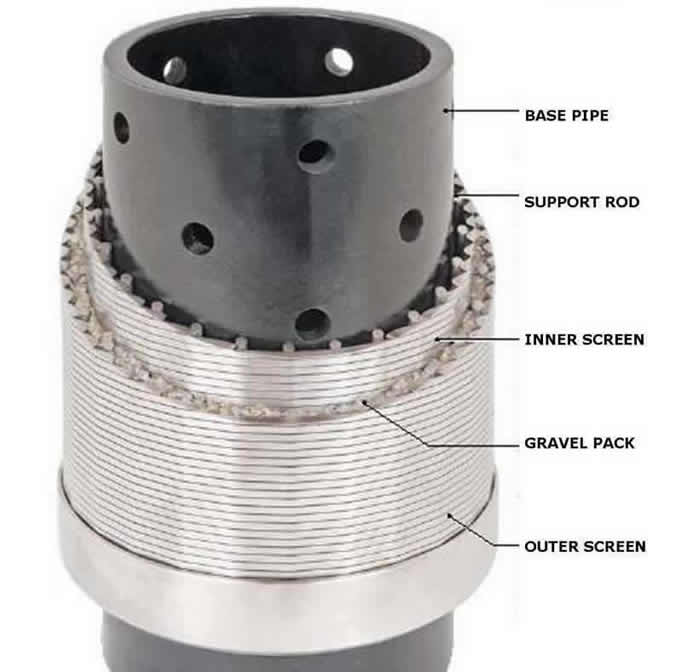

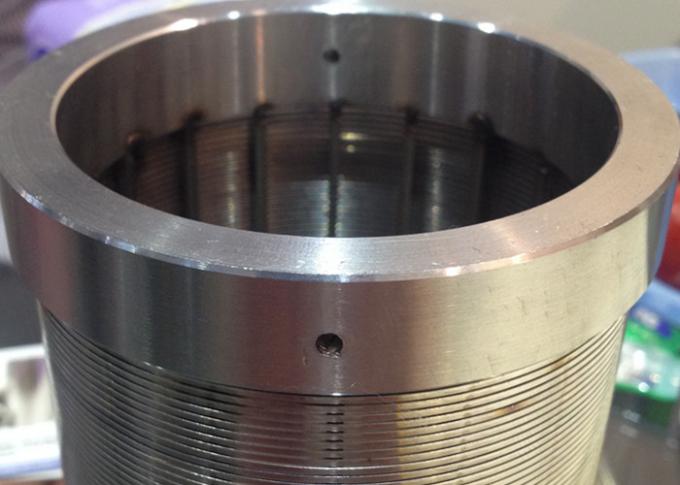

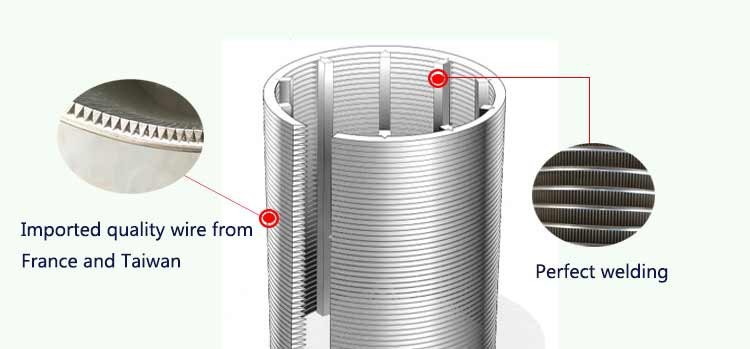

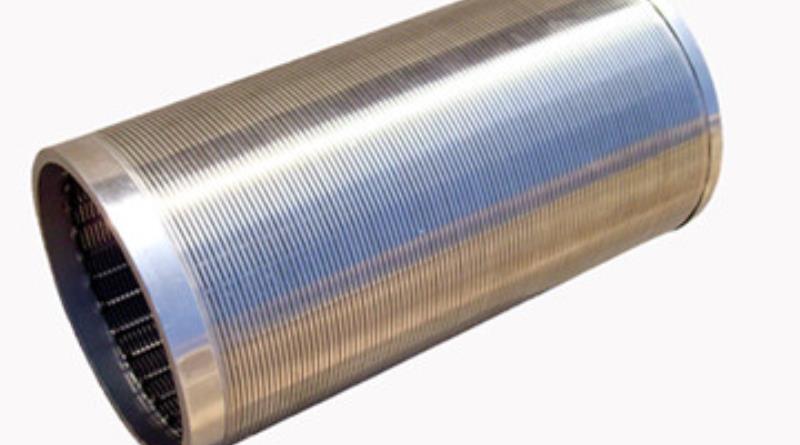

The wedge wire filter cartridge is formed by welding wire(cross section is wedge)through a special welding technology welded on the support wire, use Special equipment for resistance welding, high welding strength, uniform gap, strong corrosion resistance, effective filter area, high penetration efficiency, simple structure, minimum aperture 25μm, arbitrarily chosen by the customer.

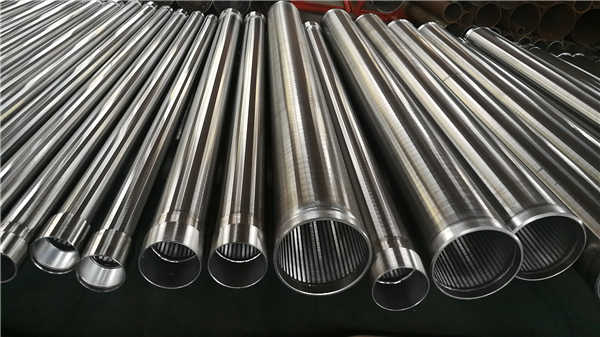

Wedge wire filter cartridges are distinguishable for their toughness as well as chemical and thermal durability. Wedge wire filter cartridges are very robust and multi-functional sieve elements.

Stainless wedge wire filter elements is a sieve made tram looped wires formed into deep wedge-shaped section. Individual wedge wires are built into ‘Panels” by threading cross rods of suitable diameter through the loops. The whole is then clamped and made secure usually by riveting or putting ring nuts over the cross rod ends or by welding.

Technical data

Filter medium: Stainless steel 1.4435.

End cap: Stainless steel 1.4435.

Gaskets: PTFE gaskets.

Filter ration: 35 – 1.000µm.

Filter area: 500 cm²/10″.

Lengths: From 4 7/8“ to 40“.

Diameter: Internal Ø 27mm. External Ø 65mm.

Temperature: Max. 230 ˚C.

Differential pressure: Max. 10 bar.

Size: 750 mm Diameter × 1800 mm Length.

Size: Diameter. 215 × 500LG.

Flow Direction: in to out.

Materials: SS 304.

Slot Opening: 250 Micron.

Flow Direction: In to Out.

Differential Pr. To: 6 Kg/cm2.

Withstand at 40 °C.

Size: Diameter. 268 × 1000LG.

Size: Diameter. 215 × 750LG.

Common Specification:

Flow Direction: in to out.

Materials: SS 304.

Slot Opening: 250 Micron.

Flow Direction: In to Out.

Differential Pr. To: 6 Kg/cm2.

Withstand at 40 °C.

| Data in reference to 10” –element with 500cm² filter area | ||||||

| 35µm | 50µm | 75µm | 100µm | 125µm | 150µm | 200µm |

| 1.8% | 2.5% | 3.7% | 4.8% | 5.9% | 7.0% | 9.1% |

| 250µm | 275µm | 300µm | 350µm | 500µm | 50µm | 1000µm |

| 11.2% | 12.1% | 13.1% | 14.9% | 20.0% | 27.3% | 33.4% |

the structure of our wedge wire screens is a combination of surface profiles and supporting profiles, fusion welded at each crossing. Carefully selected parameters guarantee that the mechanical structure of the raw materials used in the manufacture of our wedge wire screens remains unchanged, our careful and thorough pickling and passivizing process also enhances the corrosion resistance of the finished product.

applications of Wedge wire filter cartridges

Industries That Can Benefit From Wedge Wire Filtration

Petrochemical

Coatings

Mineral and aggregate processing

Plastics extrusion

Pulp and paper

Chemical

Automotive

Adhesive/sealant filtration

Other highly viscous fluids in many industries